Laser Welding in shopfitting & shop furniture production

Laser Welding in gym equipment or playground equipment

The demands to surface qualities are particularly high in shopfitting production, furniture production, gym equipment and playground equipment production.

Adhering metal spatter resulting from MIG/MAG welding processes is detrimental to the perceived qualities of the visible areas and also poses the risk of injuries.

Wobble Laser welding results in clean metal surfaces and provides optimum preparation for powder coating, paintwork or any other coating methods.

Result with wobble is: Perfect metal surfaces without additional costs of postprocessing and postprocessing equipment.

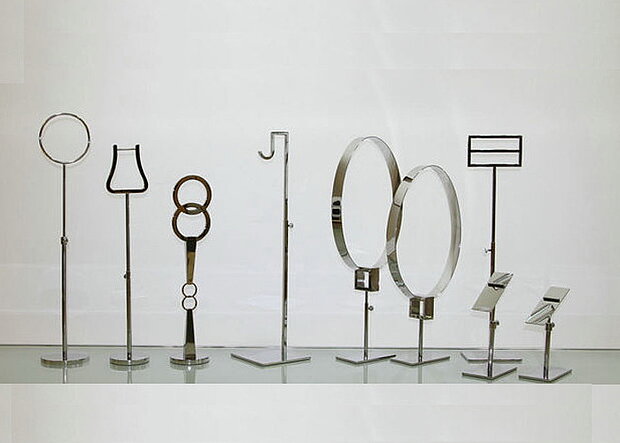

Display Props

Display props refer to props used in commercial display spaces (shopping malls, specialty stores, stores, supermarkets, etc.), such as display shelves, display cabinets, shelves and related decorations. Most of them are made of colored stainless steel square pipe and round pipe with diameter less than 100mm. Due to the diversity and beauty of product size and shape, the traditional processing method is not enough in production flexibility, processing quality and efficiency.

The Wobble-Series Welding machine of Lasermach has the characteristics of fast welding speed, narrow weld seam, good section finish, small material deformation, less heat affected area and no need for secondary processing of workpieces, which can greatly improve production efficiency, reduce production cost, improve product quality and greatly shorten the R & D and production cycle of new products, bringing you strong competitive advantage.

Chassis cabinet

Chassis cabinet is used in power, communication, medical, industrial control, mechanical shell, electrical and many other industries, such as distribution box shell, transformer chassis shell, equipment hood shell, vending / ticket machine shell, telecommunications cabinet shell, communication cabinet shell, etc. The processing problem is the waste of raw materials due to the low utilization rate of raw materials.

In addition, the market requirements for product aesthetics are increasing. The complexity of products is also increasing, and the speed of product innovation is speeding up. The traditional processing methods are inadequate in terms of production flexibility, processing efficiency and quality.

Laser welding has the characteristics of fast cutting speed, narrow welding seam, good section finish, small material deformation, less heat affected area, and no need for secondary processing of workpieces, which can greatly improve production efficiency, reduce production costs, improve product quality, greatly shorten the R & D and production cycle of new products, and help you improve the competitiveness of enterprises.

Compared with the traditional argon arc welding process, laser welding has the advantages of fast welding speed, small workpiece deformation, smooth and beautiful weld, and no need of secondary processing.

Warehouse Racks production by laser welding- Industrial storage Racks production by laser welding

Laser Welding in gym equipment or playground equipment

Laser Welding in the Fitness and gym field

Manufacturing Fitness Equipment with the laser welder

Producing high-quality fitness equipment is the most obvious use of laser welding in the fitness industry. All of this fitness equipment require metal frames. This equipment requires a lot of pipes, tubes, and sheet processing.

Fitness equipment like weight lifting machines and treadmills can be welded with this equipment. The use of force on this equipment is obvious as they are used in strenuous training. Laser welding machine gives them durable and strong bond.

- Resistance Band and Cables: Resistance bands are generally made with rubber or other stretchable material but may have metal endings or holders. Using metal handles can handle high tension.

- Dumbbells, Barbels, and Kettlebells: These small handheld fitness equipment have metal parts. The laser welding machines can add weight plates, handles, and other metal parts to the handles of dumbbells and barbells, creating a strong bond that can withstand repeated drops and impacts.

- Cardio machine components: Expensive cardio machines require metal brackets, frames, and other components. So do the stationary bikes and rowing machines, creating a secure and stable platform for users.

- Gym Decor: Besides making fitness gear and equipment, a laser machine makes it easy to weld different racks, metal shelves, and decor pieces in the fitness industry.

- Creating Custom Metal Products for Training: Laser welding machines can help you customize your equipment to meet individual needs. You can make or customize gears to suit your individual needs. A laser welding machine helps you create custom metal products for your gym. You can create custom logos.

- Repairing Gym Equipment: Besides creating equipment, a laser machine helps you to give instant repair if any joints or frames need quick fixes.