PhotonWeld © - the new reference in real sustainable Laser Welding

The Best LaserWelding machines for handheld, Robot, Cobot and automation.

Welcome to LaserMach, the laser Welding specialist

Companies often try to distinguish themselves in as many specialist areas as possible.

We deliberately concentrate on one: laser welding technology.

We design our laser welding solutions for you exclusively in Belgium.

This is where our expertise lies and where we deliver complete technical solutions that set quality world standards.

THE WORLD-CLASS LASER WELDING MACHINE MANUFACTURER

PhotonWeld Series: The Best or Nothing!

Making the leap to laser welding often raises many questions: which system to choose, how to integrate it into day-to-day production, what training operators will need, or when it will truly become profitable. As a result, many companies continue using TIG/MIG—leading to more rework, more grinding, more polishing, more distortion, and more time lost on finishing.

The PhotonWeld-Pro laser welders were created to simplify that decision: an industrial laser welding system that welds, cuts, and cleans from day one, can be operated by any operator, and fits just as well into a standalone workstation as into a complete welding solution or Welding Robot or Cobot.

That’s why we invite you to tell us about your case. Give us a call or fill out the form and our technical-commercial team will contact you to review your needs and explain—with no obligation—how the PhotonWeld-Pro can fit into your production, what results you can expect, and what the next steps would be to introduce laser welding into your processes with complete peace of mind.

PhotonWeld: We are laserwelding

New Handheld Laser technologies contribute to the development of heavy industry

Lasermach offers a broad range of laser welding equipment perfectly tailored to the requirements of heavy industrial applications.

Combine our high-power Laser Brightness equipment with the expertise of our application engineers and

reap the benefits of a single-source partner offering equipment and knowledge leadership.

PRODUCT SOLUTIONS

Lower your operating costs and increase your output with our laser Welding products designed around your business.

From single machines to complete packages, Lasermach's full range of PhotonWeld heavy fabrication solutions are designed to increase productivity and perform in even the most demanding environments

PhotonWeld A-Pro Series

Deep welding with low power

PhotonWeld MASTER-Pro Series

Master Pro X Series: The Heavy Workhorses

PhotonWeld Lite S-Pro Series

High-Speed Thin-Plate laser Welding

SOON AVAILABLE

Fastest thin plate laser welding machine

Worry-Free & Cost-Effective laser Welding Machine

Reliable, Stable & Easy to Maintain

THE FORERUNNER OF HANDHELD LASER WELDING

Lasermach's Photonweld – Designed by Welders for Welders

Lasermach is, as one of the first on the laser welding market, clearly the design leader of the handheld laser welding industry. We are committed to boosting the quality and productivity of laser welding by continuous development and improvement of the laser welding machines and by working for more ecological and more economical Solutions. Lasermach® supplies sustainable products, revolutionary new solutions, and services for professionals from industrial welding companies to single contractors. The usability and reliability of our products is our basic guiding principle. We operate with a highly skilled partner network covering many countries to make its expertise locally available. Headquartered in Belgium, with production facilities in Romania and Asia, Lasermach is serving you worldwide today.

2024 Silver: ---PhotonWeld A-PRO Series --- : Our new design got Second place at innovation awards Euroblech 2024 in Joining Technology Category

Premium Heat-pump direct cooled Portable, rugged and rain proof laser Welding Machine, 100% duty load 7/7 24/24

2025 Silver: PhotonWeld Master-Pro Series: Second place at innovation awards Blechexpo/Schweisstec 2025 in Joining Technology Category

10 2025 Stuttgart: Again Silver medal for innovation in the most important exhibition of 2025 in Europe

PhotonWeld A-Pro

Laser Welding from 0,2 mm till 9,0 mm welding thru from one side

PhotonWeld PRO Series: A-Pro

Available in 7 Handheld models and in 7 Cobot models

PhotonWeld A-PRO-T45:

Welds: 4,5 mm Stainless Steel - 3,0 mm Aluminium

PhotonWeld A-PRO-T55:

Welds: 5,5mm Stainless Steel - 4,5 mm Aluminium

PhotonWeld A-PRO-T70:

Welds: 7,0 mm Stainless Steel - 6,0 mm Aluminium

PhotonWeld A-PRO-T90

Welds: 9,0 mm Stainless Steel - 7,5 mm Aluminium

PLUS Cleaning, Cuttting, Deburring, pointwelding, rounding, ...

PhotonWeld Master-Pro X-Series

Laser Welding till 10,0 mm welding thru from one side

PhotonWeld Master-PRO Series:

Available in 3 Heavy Duty Handheld models

Maximum Welding Penetration

PhotonWeld MASTER-PRO-X100:

Welds: 10,0 mm Stainless Steel - 9,0 mm Aluminium

PhotonWeld MASTER-PRO-X80:

Welds: 8,5mm Stainless Steel - 7,5 mm Aluminium

PhotonWeld MASTER-PRO-T60:

Welds: 6,5 mm Stainless Steel - 5,0 mm Aluminium

maximum 8mm Wide welding

PLUS Cleaning, Cuttting, Deburring, pointwelding, rounding, ...

PhotonWeld-PRO Series

The Best Laser Welding Machine even made better!

Premium Heat-pump cooled Portable, rugged and rain proof laser Welding Machine

Works under 100% load continue 7/7 - 24/24

Works at ambient temperature from -30°C till +60°C

Feels and Looks like a normal Welding machine

Laser Welding Machine with the highest energy efficiency on the market

BEFORE AND AFTER THE ROUGH HAMER ATTACK ON A PHOTONWELD WELDED PART

If this is not "raping" a nice workpiece, then nothing is it!!

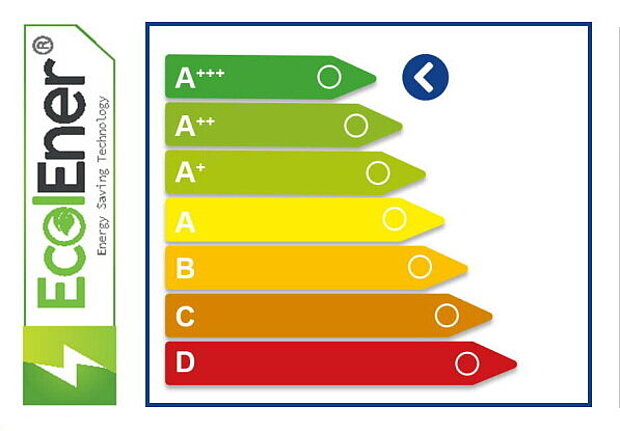

LOW ENERGY CONSUMPTION - LOW ECOLOGICAL IMPACT - GREAT FOR YOU WALLET

PhotonWeld-Series: Your most clever investment! Minimal 22% less energy consumption compared to any other laser welding machine and minimal 70% les energy consumption to any other welding method

PhotonWeld A-Pro: Leading Companies to a Low Carbon Future!

84% less CO2 Production with a PhotonWeld

Arc welding produces 9.82 grams CO2 per second, PhotonWeld only 1,57 gram

Normal Welding = 4,8 TON CO2/Shift/year ←→ PhotonWeld A-Pro = 0,62 TON CO2

Changing from conventional welding to PhotonWeld A-Pro:

=>4,2 TON CO2 less produced in one year per shift per machine

4,2 ton CO2 = 32.000km driving with a normal 1600cc diesel car CO2 production

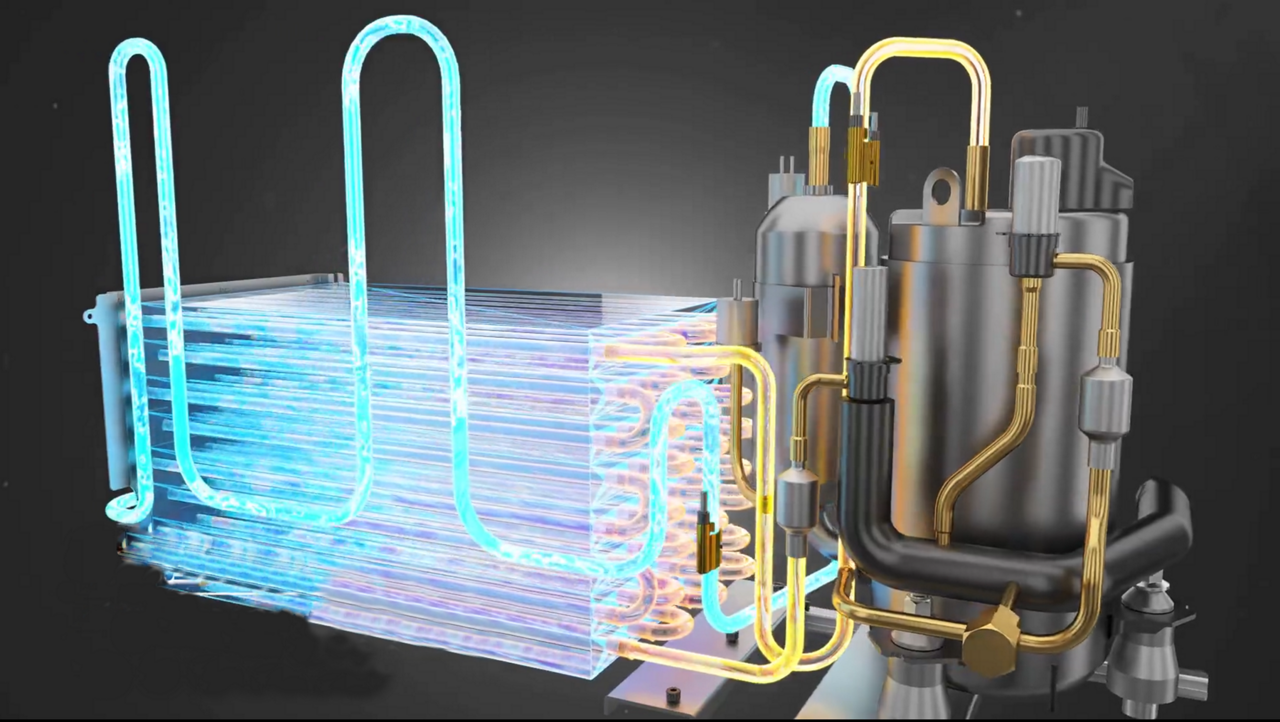

Why is our Air-cooled PhotonWeld series with liquid gas direct injection so much better than all the other air cooled laser Welding Machines?

Because we are the only one with an super efficient heatpump inside that keeps the machine cool in any situation.

Photonweld-A series are the only laserwelding machines that are:

=>able to work 100% of the time on 100% duty (full power)

=>work from -30°C till+60°C

=>equipped with an invertor driven compressor pump

=>equipped with a super economical and ecological heat pump

First Laser Welding machine with

liquid gas injection cooling direct into the laser

=>IPX3 rain-proof for PRO Model

Consumes 22% to 65 % less energy than other LaserWelding Machines

Is air-cooled

No need heating up time in the winter

Runs from a standard 240v mono plug

......

World leader in high brightness laser welding machines - Master in Energy Saving

PhotonWeld-A-PRO Series: Simply "The" Best

PhotonWeld: Equiped with all CE requested Safety accesoiries connections as standard

Laser beam Emission indicator + external emission warning indicator control as STANDARD

PhotonWeld Series: Full CE Safety certified Handheld Laser Welding Machines

Equiped with all CE requested Safety accesoiries connections as standard

- Laser beam Emission indicator + external emission warning indicator control

- Remote interlock connector with Multi safety interlocks:

- Nozzle contact interlock

- Door contact (external) interlock

- Foot pedal (dead’s men pedal) interlock (opt.),

- Hardware Key control lock

- Internal and external double wired emergency stop (opt.)

- Failsafe start-stop control

WE HOLD SAFETY OF PEOPLE IN HIGH ESTEEM!

Complete upgraded version!!!

Perfect laser Welding!!

Better Portable Laser Welding Machine, you CANNOT find!

Rain resistant : class IPX3

Dust & Dirt Proof :class IP4X

Noise level highly reduced : below 50db

Runs on 220V 16A Mono standard plug!

Cooling direct into the lasersource with liquid gas injection (heatpump)

= 3x more efficient and till 70% more energy saving in the cooling cycle

Whether it is in the severe cold of -20°C, or in the scorching heat of 60°C, even in a high humidity environment of 90%, the new PhotonWeld A-Pro can achieve 7*24 hours of uninterrupted continuous laser output (uptime = 100% + duty = 100%).

PhotonWeld PRO Series

Under Construction

PhotonWeld A-PRO Series

Simply the Best

PhotonWeld MASTER-Pro Series

Teh Power Laser Welding Machine

PhotonWeld LITE PRO HS Series

HIGH Speed Laser Welding

VIDEO: Laser Welding is .... OUFFFF!

Independant laser welding machine test by "soudeurs 2.0" - click on video to view

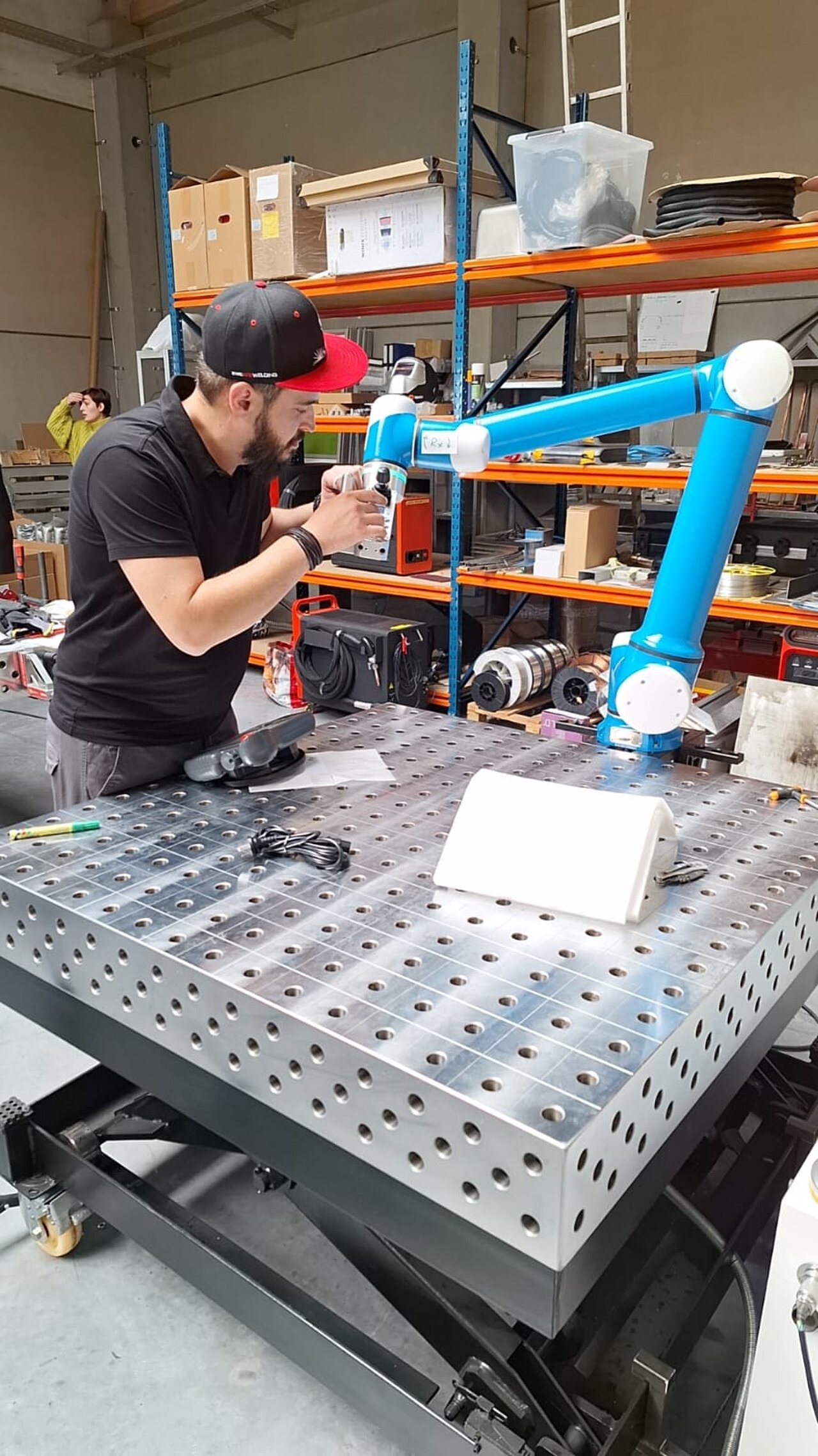

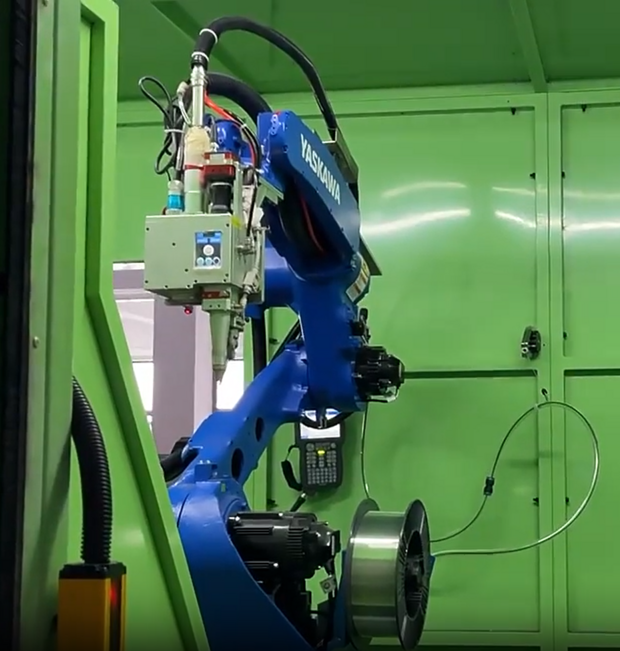

Laser Welding with COBOT - ROBOT - AUTOMATION -

Photonweld A-Pro and automation

PhotonWeld in automation

Ready made Laser Welding systems to build on new or existing robot/cobot systems or to upgrade any conventional robot welding system

PhotonWeld A-Pro CRC - The readymade Handheld Laser welder for automated production

Laser Welding Machines with simple Robot, Cobot, automation, .. . interface adaptyable to any automation application

PhotonWeld A-Pro R6 - Ready made Robot Laser Welding system

Specific for upgrade of exisitng robots/cobots for mas production!

PhotonWeld A-Pro R7 Series

With Full robot controlled 2 axis Wobble laser welding head

Laser Safety - Personal Laser Safety - Environmental laser safety

PhotonWeld and laser safety

SAFETY – WE TAKE IT VERY SERIOUS

You too have to take it VERY serious!

Never forget your and your colleagues personal safety at laser works.

Laser radiation of infrared fibre lasers can cause serious and lasting damage to the human eye – so a handheld laser is not a toy. But simple precautions and our inherent safety design make this a safe solution that meets the requirements of globally active customers and their safety organizations.

The Ugly Truth About Laser Radiation Exposure To Your Eyes

In the time that it takes to blink an eye, laser radiation damage to the eye may have already occurred. Unprotected exposure of your eyes to lasers can result in the development of cataracts or even a corneal burn, which can result in vision loss.

If you are working with or around lasers, it is very important to understand the consequences of laser radiation exposure and the safety precautions you should take when working around them.

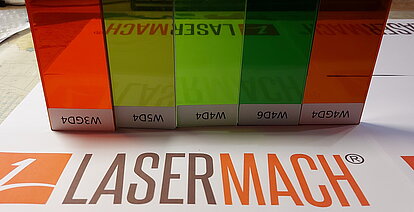

Protection at laser Welding

Our Range of protection tools for Laser Welding radiation

Laser Welding Curtains

PhotonSafe Laser Welding protection Curtains - Laser Barrier curtains

Laser Welding Shields/walls

PhotonSafe laser safety barriers - laser safety shields

Laser Welding Windows - Laser Welding protection Windows

Laser safety window for laser welding machines

Laser Welding Safety Windows are used to protect against lasers' radiation while still allowing visibility.

CE Certified EN 207

Laser Window Foil - LASER WINDOW FILM

Laser protection foil to put on standard windows for full eye protection

The Lasermach Safety team is proud to provide a high-quality laser window film. Our laser protective removable window films can be used on your laser welding rooms windows to protect external persons from the glare of the welding lasers.

Laser Welding protection Glasses and -Goggles

Laser Welding protection faceshields - Laser Safety Face Shields

Laser Welding protective face shields - Laser safety and protection face shield mask .

Laser Welding Protection Clothing

Protective clothing for laser operators

Laser Welding Safety Signs - Laser safety signage

Laser Safety electronics- Laser safety controls

Laser safety signage is of crucial importance in all environments where the use of lasers is present.

PhotonWeld A-Pro + PhotonSafe Modular laser welding cabin

Complete laser Welding solution from one Supplier

Our PhotonSafe laser welding cabins are modular, adaptable installations that offers great flexibility and comfortable safety for starting to work with laser welding with a complete safe solution

More info on our Safety equipment and Modular Laser Welding Cabins

Meet our products - PhotonWeld Series: THE "BEST" or NOTHING

OUR FULL RANGE OF PREMIUM HANDHELD LASER WELDING MACHINES -

PhotonWeld A-Pro Series

A = PREMIUM LASER WELDING MACHINES Cooled by AIR COOLED Heatpump

PhotonWELD uses the new EcolEner High Efficiency Laser Source family

Lasers with record wall-plug efficiency of almost 50%.

PhotonWELD uses the new EcolEner High Efficiency Laser Source family, a new generation of kW class low-mode Ytterbium fiber lasers with record wall-plug efficiency of almost 50%. PhotonWELD Series offers an unparalleled level of reliability, have higher wall-plug efficiency, are brighter and more reliable than kW class diode lasers built by combining multiple emitters into a single output. The ECOLENER Series is perfectly suited for applications that cannot tolerate any downtime or service intervention. The EcolEner can be used in all high power application areas, including cutting, welding, brazing, cladding and surface treatment.

EcolEner ®: Sustainable ECOLogical ENERgy Saving Technology for Lasers

ECOLENER ® Photon Saving Technology

EcolEner : patented High Efficient Energy saving Technology from Lasermach

Saving minimal 22% energy compared to laser welding machines with standard laser sources

Sustainability is emerging as an important approach that manufacturing companies employ to improve their economic profitability and competitive advantage by enhancing environmental performance. Consistent with the contemporary aspects of ecological responsibility, specific forms of ECOLogical ENERgy (ECOLENER ®) saving mediate the relationship between an environmental sustainability orientation and environmental performance.

Every PhotonWeld laser Welding Machine is equipped witht the unique and patented EcolEner energy saving technology. Minimal 22% energy saving compared to any other laser source and up to 85% energy saving compared to any other Welding Machine

EcolEner ®: Sustainable ECOLogical ENERgy Saving Technology for Lasers

PhotonWeld-R Series

Robot/Cobot Ready Laser Welding Packages

PhotonWeld-R

Robot-ready laser Welding

R = ROBOT/COBOT Ready

Robot/cobot Ready laser welding packages

THE MOST ECONOMICAL WAY OF WELDING

PhotonWeld-R

ROBOT/COBOT ready made plug in laser Welding systems

Robot laser Welding Production Cells

ROBOT ready made plug in laser Welding systems

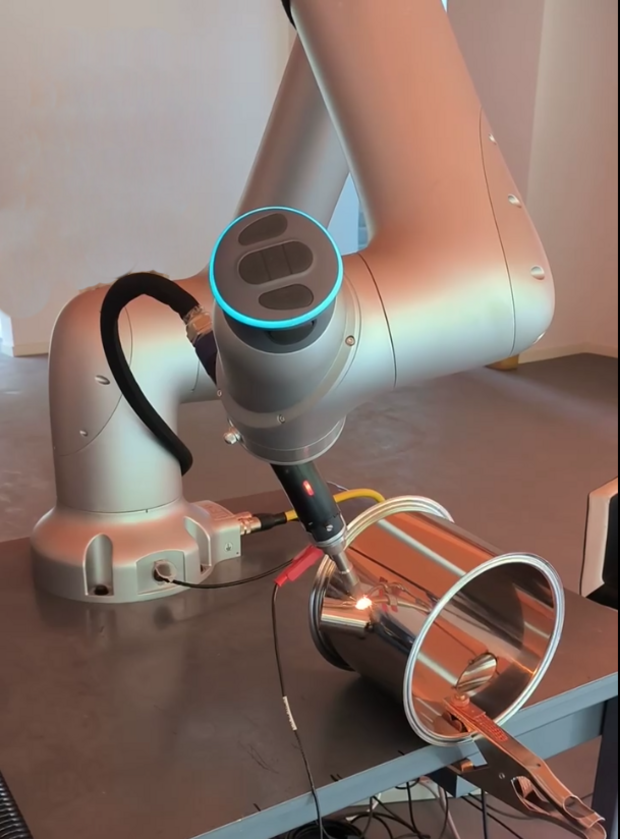

PhotonWeld-C Series

Plug and play high performant laser Welding package for cobot

PhotonWeld-C

Robot-ready laser Welding

C= COBOT Welding Machine

Cobot Laser Welding Machines

& Cobot Ready laser welding packages

THE MOST ECONOMICAL WAY OF WELDING

PhotonWeld-C

Cobot laser Welding Machine - COBOT ready made plug in laser Welding systems

Soon Available

Our PhotonWeld fiber laser welder gives you back the POLE position!

Comparison Welding: We beat them ALL

Comparison welding | Traditional welding | Laser welding | PhotonWeld laser welding |

|---|---|---|---|

Heat input to the workpiece | Very high | Low | Very Low |

Deformation of the workpiece, undercut | Big | Small | Very Small |

Bond strength to base metal | General | Good | Very good |

Follow up treatment | Polishing | Rarely need polishing | No need or rarely need polishing |

Welding speed | General | More than 2~4 times arc welding | More than 2~4 times arc welding |

Applicable material | Stainless Steel, Carbon steel, Galvanized sheet | Stainless Steel, Carbon steel, Galvanized sheet, brass,.. | Stainless Steel, Carbon steel, Galvanized sheet,brass,... |

Consumables | More consumables | Less consumables | Less consumables |

Operation difficulty | Complicated | General | Very easy |

Operator safety | Unsafety | Safety | Safety is VERY High |

Environmental protection impact | Not environmentally friendly | Environmentally friendly | Environmentally friendly |

Welding fault tolerance | Good | Bad | VERY Good |

Wobble/Swing welding | No | No | Yes |

Spot width adjustable | No | No | Yes |

Welding quality comparison | Bad | General | Very Good |

Designed in Belgium

Deliver business value

Today more than ever, outstanding design means providing answers to the challenges of our time, promoting thinking in circular models and realising visions of a better world based on the design of actions.

How can the sustainable transformation of our industry and society succeed?

By simply make it better than the others!

Lasermach opened the first European Laser Welding Innovation Center in the center of Europe (Mouscron - Belgium)

Laser Welding Machine with Professional training and instruction included in our Laser Welding DEMO/TEST/TRAINING Centrum.

What Types of Material Can be Welded with our PhotonWeld laser welding machines?

What Metals can be Successfully Welded with Fiber Lasers?

Lasers can weld many different types of materials together. Stainless steel, titanium,nickel, aluminum, molybdenum, and Inconel are just a few of the metals that are

well-suited to laser welding. What is important to note, however, is that not all metal combinations are weldable.

Aluminum, for example, can be laser welded. However,only dissimilar grades of aluminum can be welded together due to a high probability of cracking.

This is one area where laser welding differs from conventional welding. In conventional welding, the metals don’t bond directly with one another, but rather with the filler material being used. This can be a major factor in determining whether or not a particular application lends itself to laser welding.

PhotonWeld: High efficient portable handheld Laser Welding Machines

PhotonWeld: Simply the best handheld laser Welding Machine

www.PhotonWeld.com

العربية - لحام بحزمة ليزرية▪ বাংলা - লেজার বীম ওয়েল্ডিং▪ Català - Soldadura per raig làser▪ Deutsch - Laserschweißen▪ English - Laser beam welding▪ Español - Soldadura por rayo láser▪ Français - Soudage laser▪ עברית - ריתוך בלייזר▪ Hrvatski - Zavarivanje laserskim snopom▪ Italiano - Saldatura laser▪ 日本語 - レーザー溶接▪ Polski - Spawanie laserowe▪ Português - Soldagem a laser▪ Română - Sudarea cu laser▪ Русский - Сварка лазером▪ Slovenščina - Lasersko varjenje▪ Svenska - Lasersvetsning▪ తెలుగు - లేజరు బీమ్ వెల్డింగు▪ Українська - Лазерне зварювання▪ 中文 - 激光焊

Who sells laser welding equipment - Who sells laser welding machines? - where can we buy laser welding machines? Who sells laser welding equipment - Who sells laser welding machines? - where can we buy laser welding machçines? Wer verkauft Laserschweißgeräte - Wer verkauft Laserschweißgeräte? - Wo können wir Laserschweißmaschinen kaufen? - Qui vend des équipements de soudage au laser - Qui vend des machines de soudage au laser? - Chi vende attrezzature per saldatura laser - Chi vende saldatrici laser? - dove si possono acquistare saldatrici laser? – ¿Quién vende equipos de soldadura láser? ¿Quién vende máquinas de soldadura láser? - ¿Dónde podemos comprar máquinas de soldadura láser? - Vem säljer lasersvetsutrustning - Vem säljer lasersvetsmaskiner? - var kan vi köpa lasersvetsmaskiner? - Kim lazer kaynak ekipmanı satar - Kim lazer kaynak makineleri satar? - Lazer kaynak makinelerini nereden satın alabiliriz? - Kdo prodává laserové svařovací zařízení - Kdo prodává laserové svařovací stroje? - kde si můžeme koupit laserové svařovací stroje? - Kdo prodaja opremo za lasersko varjenje - Kdo prodaja stroje za lasersko varjenje? - kje lahko kupimo stroje za lasersko varjenje? - Kto predáva laserové zváracie zariadenie - Kto predáva laserové zváracie stroje? - kde si môžeme kúpiť laserové zváracie stroje? - Ко продаје опрему за ласерско заваривање - Ко продаје машине за ласерско заваривање? - где можемо купити машине за ласерско заваривање? - Кто продает оборудование для лазерно…