Laser welding has become a widely used welding process in many manufacturing fields. Handheld laser welding is only accelerating this popularity.

The technology of laser welding is constantly improving, and the process is becoming more sophisticated.

So, what are the factors that affect the results of laser welding?

Welding Equipment in use

First factor influencing the laser welding results!

Welding Equipment

Welding Equipment Performance and Maintenance

The quality of welding equipment directly influences the integrity of welds. Complex equipment with higher levels of mechanization and automation particularly impacts welding quality.

Hence, it's imperative for such equipment to exhibit superior performance and stability. Prior to usage, welding equipment should undergo thorough inspection and testing, with a robust routine inspection system established for all operational welding equipment.

For laser welding machines, meticulous attention must be paid to the following aspects:

- Laser Types: The choice between pulsed or continuous lasers should align with the material being welded.

- Beam Mode: Optimal focusing performance is indicated by a lower beam mode order, resulting in finer spot size and higher power density, thus enhancing the welding depth-to-width ratio.

- Single Mode or Multi Mode Laser: Considerations regarding laser beam properties and their compatibility with the welding process.

- Output Power Stability: Consistency in laser output power ensures uniform welding outcomes.

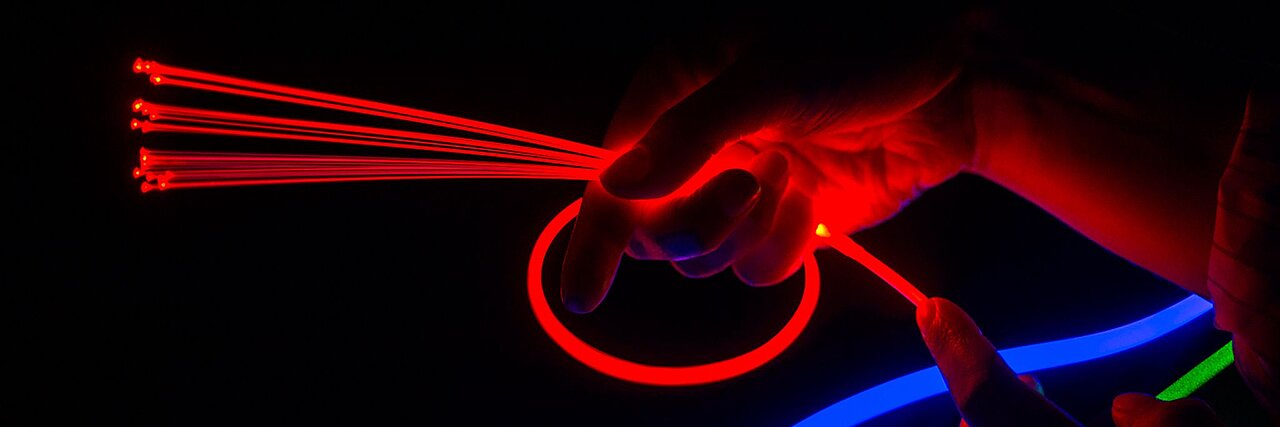

- Optical Transmission and Focusing Systems: Maintenance of these components is crucial as they can degrade over time, affecting transmittance and causing a thermal lens effect. Regular monitoring and quality checks are essential to uphold welding standards.

Furthermore, factors such as environmental requirements, adjust-ability, operational space, and error correction capabilities should also be carefully considered to ensure seamless operation of welding equipment.

Welding material - Welding Work-pieces

Second factor influencing the laser welding results!

Welding material - Welding Work-pieces

In order to ensure welding quality, the welding quality of raw materials is very important. In the initial stage of production, that is, before feeding materials, it is necessary to check and control the materials and eventual test-weld on some scrap of the material to weld, this in order to stabilize production and stabilize the quality of welded products.

- Absorption Rate of Material to be Welded: The compatibility of the laser beam with the material depends on important properties such as absorption rate, reflectivity, thermal conductivity, with absorption rate being the most critical. Some materials have excellent absorption rates for lasers, while others have poor or zero absorption.

- Uniformity of Material for Welding Workpieces: The uniformity of the material directly affects welding quality. For example, when welding aluminum alloys, uneven distribution of alloy elements or varying impurity content can lead to welding defects such as blowholes, undercutting, and craters. Non-uniform material dimensions, especially thickness and height, can result in poor fit with fixtures, deviations from the focal point, and suboptimal welding quality.

- Accuracy of Welding Workpiece Assembly: Due to the small size of the laser spot and narrow weld seam, welding typically does not involve adding filler metal. If the assembly has excessive gaps due to poor fit, the laser beam may pass through the gap without melting the base material or cause noticeable undercutting and craters.

- Cleanliness of the Workpiece to be Welded: Insufficient surface cleanliness with impurities can also lead to poor welding quality.

- Burr-less and straight edges improve drastically the result. Burrs result in an unstable welding speed at hand laser welding and as result an unstable welding bead.

Welding process parameters include laser output power, welding speed, laser waveform, pulse frequency, defocus amount, and pulse width.

Third factor influencing the laser welding results!

Welding Process Parameters

Welding process parameters include laser output power, welding speed, laser waveform, pulse frequency, defocus amount, and pulse width.

- Output Power: Adjusting the output power of the laser during welding is crucial and depends on the thickness of the material being welded. Both excessive and insufficient power output can impact the depth of fusion. Laser welding operates based on a threshold energy density, where below this value, the melt depth remains shallow. However, once this threshold is surpassed, the melt depth significantly increases. Plasma generation occurs only when the laser power density exceeds this threshold, indicating stable deep penetration welding. If the power falls below this threshold, only surface melting occurs, leading to stable heat conduction welding. However, when the power density nears critical conditions for pore formation, the welding process becomes unstable, resulting in fluctuations in melt depth.

- Output Power Stability: Consistency in the output power of the laser enhances welding uniformity. Output power stability primarily depends on the quality of the laser equipment.

- Controlling Heat Input: Efficient control of heat input is essential in laser welding to prevent adverse outcomes such as excessive distortion or surface damage. Various parameters contribute to regulating heat input effectively:

- Focal Length: Adjusting the focal length enables precise energy concentration control.

- Focus Position: Proper focus point positioning ensures optimal energy delivery.

- Plate Thickness: Workpiece thickness affects heat dissipation and penetration depth.

- Spot Size: Modifying spot size allows flexibility in managing power density.

- Melt Depth: Monitoring melt depth is crucial for consistent weld quality, controlled by welding speed adjustments.

- Welding Density: Higher welding density results in faster welding speeds for a given spot and depth.

- Welding Speed: Welding speed influences fusion depth, with the choice between high and low speeds depending on material thickness and desired quality. Higher speeds are suitable for thin materials, while lower speeds are preferable for thicker materials.

- Laser Waveform: Different waveforms are used depending on material reflectivity. For high-reflectivity materials, trapezoidal waveforms can overcome reflectivity barriers, while rectangular or gradually attenuating waveforms are preferred for low-reflectivity metals.

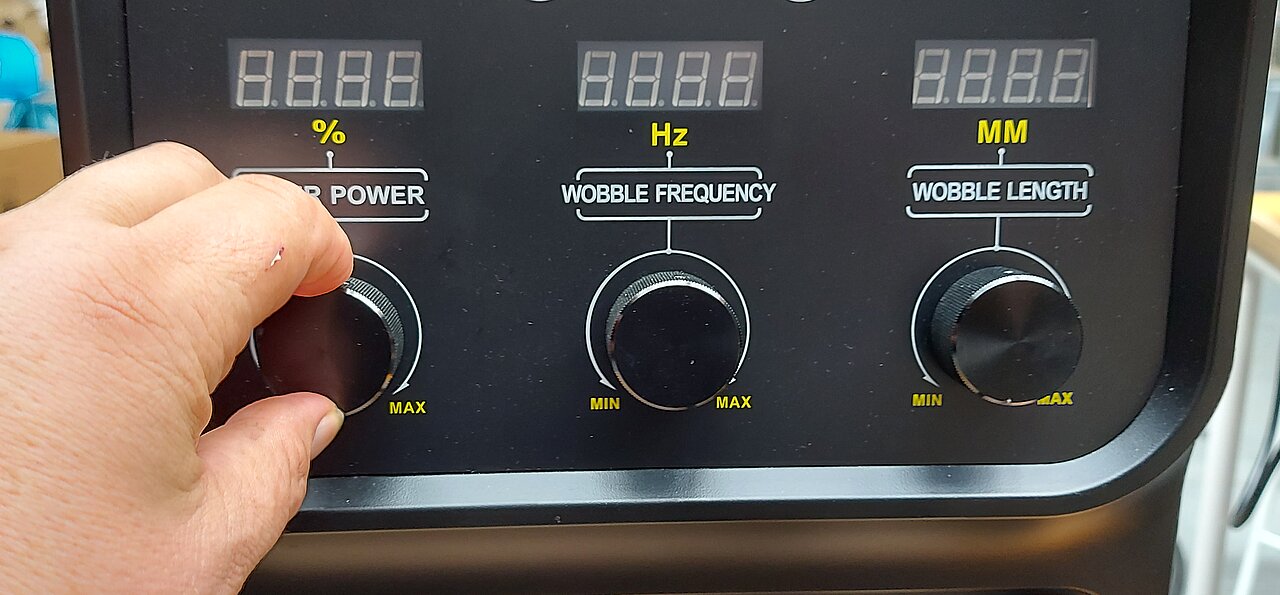

- Wobble Frequency: Frequency selection affects weld seam appearance and quality. Proper frequency choice is crucial to maintain a smooth weld seam.

- Pulse Frequency: Matching pulse frequency, beam size, and welding speed is essential for achieving the desired overlap rate. Excessive pulse frequency can lead to penetration or weld spatter.

- Defocus Amount: Positive and negative defocusing affect penetration and spattering, with negative defocusing suitable for achieving deeper melt depths.

- Pulse Width: Longer pulse widths result in larger weld diameters and deeper melt depths.

- Width of Welding Seam: The width of the laser beam impacts weld seam performance, influencing the depth-to-width ratio and overall quality.

It's important to consider other factors such as gas type and material absorption, and adjust parameters accordingly to optimize welding results. Conducting multiple trials and fine-tuning parameters can lead to improved welding outcomes.

Worktable

Fourth factor influencing the laser welding results!

Worktable

The worktable directly influences the welding effect and processing efficiency. If the welding platform is not level or not vertical, the quality of the weld seam will be affected. Additionally, if the welding platform surface contains impurities such as oil and dust, these impurities can mix into the weld seam during the welding process, affecting the density and strength of the weld. In large-scale production, fully automatic laser welding machines often use automatic worktables to improve production efficiency, so the difference in worktables can have a significant impact on welding results.

Welding Fixtures

Fifth factor influencing the laser welding results!

Welding Fixtures

Welding fixtures ensure the precise positioning and secure clamping of welded components, facilitating the installation and welding of components and meeting the process requirements for structural accuracy. Actively promoting and applying fixtures that are compatible with product structures in modern welding production plays a crucial role in enhancing product quality, reducing labor intensity for workers, and accelerating the mechanization and automation of the welding process.

Welding Gas - Protective Gas

Sixth factor influencing the laser welding results!

Protective Gas

Protective gas, or shielding gas, is also one of the important factors affecting welding quality. Protective gas is an inert gas used to protect the molten pool during the laser welding process. Some materials may not require protective gas if surface oxidation is not a concern, but it is generally needed for most applications.

Choosing appropriate shielding gases in the welding process helps minimize spatter formation and maintain arc stability with laser welding equipment. Handheld laser welding machines can also benefit from the use of shielding gases.

Protective gas serves various purposes, such as expelling or weakening plasma (which is easily generated during laser welding and has effects on laser absorption, refraction, and reflection), increasing the cooling rate of the weld seam, reducing the degree of surface oxidation in the weld seam, and improving the surface appearance of the weld. Commonly employed protective gases include nitrogen, argon, helium, as well as mixtures of argon and helium.

For more information about shielding gas in laser welding, you can see here.

Additional Considerations

In addition to material selection, heat control, …. , several other factors influence laser welding parameters:

- Filler metal: Depending on the application requirements, filler metals can enhance strength or improve corrosion resistance.

- joint design:

- Machine labor cost: Optimizing laser welding machine parameters can reduce labor costs by improving efficiency and minimizing rework on the equipment.

- Surface cleanness

By considering these key factors, welders can determine the optimal laser welding parameters for each specific application. This ensures high-quality welds with minimal distortion and reliable performance.

The Interplay of Parameters

The Laser welding parameters play a crucial role in the overall laser welding process. Understanding how different parameters interact with each other is essential for achieving optimal results. During laser welding, various process parameters come into play, affecting the stability, deformation, penetration, power, temperature, and properties of the weld. Let’s delve into some key aspects:

Parameter Combinations

Different parameter combinations yield varying outcomes in specific applications. For example:

- Higher power settings on a laser welding machine increase weld penetration but may also lead to increased heat input.

- Adjusting the focal point of a laser welding machine can significantly impact surface quality and allow for precise control of heat distribution.

An increase in laser power might demand a corresponding adjustment in welding speed to maintain the desired weld depth and quality. Similarly, modifying the pulse duration can impact the heat affected zone and require alterations in shielding gas flow rate or type.

- Consider another example: If the beam diameter is decreased (resulting in a more concentrated focus), the laser’s intensity increases. This may necessitate a reduction in laser power or an increase in welding speed to prevent burn-through or excessive weld width.

Balancing Trade-offs

When selecting parameters, it’s crucial to strike a balance between speed, quality, and cost. This involves considering factors such as:

- Welding speed: Faster speeds may compromise weld quality.

- Heat input: High heat input can affect material properties.

- Surface preparation: Proper cleaning and preparation contribute to better results.

Material Considerations

While machines and lasers function based on set parameters, the materials being welded have their own intrinsic properties, like melting point, reflectivity, and thermal conductivity. These can introduce another layer of variability into the laser welding process. Thus, understanding material responses and adjusting parameters holistically becomes paramount. Different materials require specific parameter adjustments due to variations in their thermal conductivity and melting points. Factors to consider include:

- Material surface condition: Surface roughness affects laser absorption.

- Composite materials: Welding dissimilar materials requires careful parameter selection.

Understanding how these parameters interact enables welders to optimize their laser welding processes for desired outcomes while minimizing defects or issues that may arise during laser welding.

Conclusion

In conclusion, the effectiveness of laser welding is influenced by a big mix of factors, ranging from the characteristics of the welding equipment to the intricacies of the welding process and the quality of the workpieces involved.

Selecting the appropriate laser type, ensuring stability in output power, and maintaining the integrity of optical components are critical considerations in welding equipment. The properties of the materials being welded, such as absorption rate, uniformity, and cleanliness, play a pivotal role in determining the overall welding quality.

Fine-tuning welding process parameters, including output power, welding speed, laser waveform, pulse frequency, defocus amount, and pulse width, is essential for achieving the desired welding results. Moreover, the condition of the worktable, the use of suitable welding fixtures, and the application of protective gas further contribute to the overall success of the laser welding process.

As laser welding technology continues to advance, understanding and optimizing these factors will be key to pushing the boundaries of precision, efficiency, and quality in various manufacturing applications.

The intricate interplay of these elements underscores the importance of a holistic approach to laser welding, where careful consideration of each factor collectively contributes to the success of the welding process and the quality of the final product.