Offering Laser Safety Glasses and Laser Safety Goggles

When buying laser safety glasses and goggles, be sure to select the laser glasses to block or attenuate the appropriate wavelength range and Optical Density (OD).

We are offering a full product line of laser protection glasses which protect the eyes from Class 4 laser systems.

All Lasermach's Safety eye-wear meet or exceed ANSI Standards for the appropriate laser safety systems and

is special adapted to laser welding and laser cleaning

Standard handheld laser welding and laser cleaning is using the Infrared A laser Range of 1076 nm (+-5nm)

Why Laser Safety Glasses?

The Ugly Truth About Laser Radiation Exposure To Your Eyes

In the time that it takes to blink an eye, laser radiation damage to the eye may have already occurred. Unprotected exposure of your eyes to lasers can result in the development of cataracts or even a corneal burn, which can result in vision loss.

If you are working with or around lasers, it is very important to understand the consequences of laser radiation exposure and the safety precautions you should take when working around them.

Laser Wavelengths

Just like ordinary light, laser beams come in all colors. They measure light in nanometers (nm), the light’s wavelength.

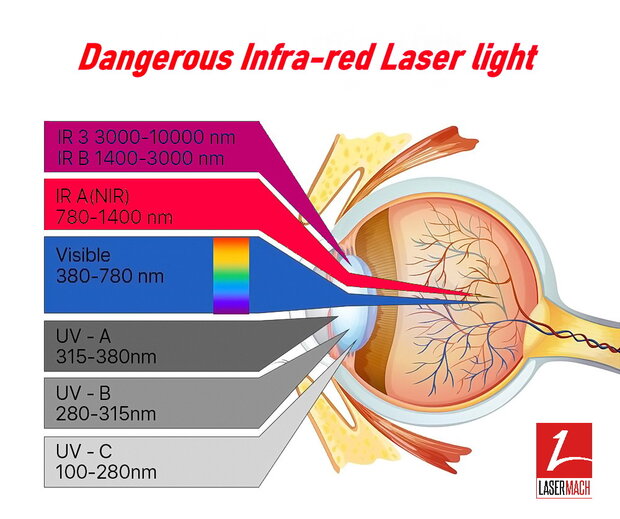

There are three main ranges of light wavelengths:

- Ultraviolet – 100-400 nm

- Visible – 440-750 nm - The visible range of laser light goes from violet to red just like a rainbow.

- Infrared – 750nm to 1mm (Laser Welding frequency belongs to the IR-light range (Infra-Red)

Infrared lasers pose a particular hazard. Because they cannot be seen, they do not trigger the eye’s blink reflex.

Our Welding Lasers use the dangerous Infrared laserlight

Danger of Laser radiation

Lasers used for laser welding applications radiate in the infrared spectra, which are not visible to the humaneye.

The intensive fiber laser light radiate in the visible spectrum but invisible for humans, is especially dangerous to the eye. Fibre laser radiation penetrate through to the retina which can be destroyed irrevocably by relatively little radiation.

Misdirected laser radiation can come directly from the laser and threaten the eyes as a result of a faulty parameter setting, an opened cover, a displaced mirror etc. Other hazards include skin burn or inflammation from combustible materials as a result of misdirected laserradiation. The greatest hazard, however, usually stems from reflected laser radiation: the major share of the laser radiation is reflected by coldmaterial first. To this we can add reflections of work piece edges, as a result of turbulence in the weld pool etc.

Misdirected radiation and reflections must be blocked off. That is why the law stipulates that the laser beam and the work zone must be in an enclosure. Beyond that, all those present, and the machine operators in particular, should wear protective goggles that are appropriate for the laser radiation being used. Fbre laser radiation are very dangerous to the eye and require special protective measures andapproved safety goggles.

Standard protective welding goggles made of glass or acrylic glass are not suitable at all,

as glass and acrylic glass allow fibre laser radiation to pass through!

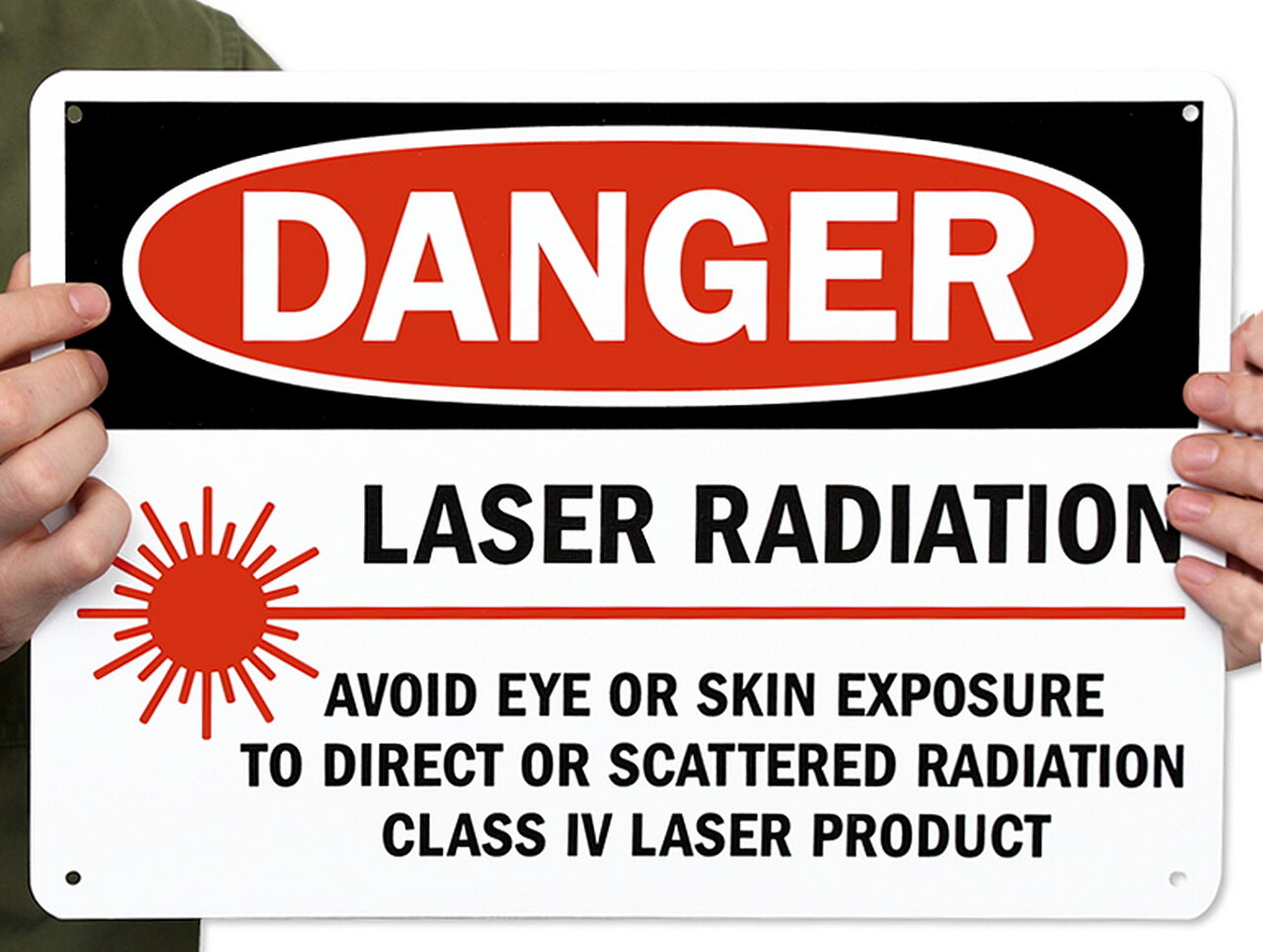

Laser Safety: Under EN 60825-1 classification scheme, lasers are classified into seven hazard classes depending on the accessible emission limits.

The scheme is a measure of the laser’s ability to produce injuries to personnel.

The classes are as follows:

- Class 1: the radiation is not dangerous and no protection equipment needed

- Class 1M: the radiation is not dangerous when used without optical instruments but may become dangerous when used in combination with optical instruments - no protective equipment required if used without optical instruments

- Class 2: The radiation emitted is not dangerous due to aversion responses including the blink reflex – no protective equipment needed

- Class 2M: The radiation emitted is not dangerous due to aversion responses including the blink reflex but may become dangerous when used with optical instruments - no protective equipment required if used without optical instruments

- Class 3R: The radiation from these lasers exceeds the maximum permissible exposure values so is dangerous to the eyes and safety glasses are recommended

- Class 3B: Direct laser view is dangerous so safety glasses are mandatory ⇒ fiber laser welding

- Class 4: Both direct and diffuse radiation is dangerous so personal safety equipment is necessary ⇒ all handheld fiber laser welding machines and laser cleaning Machines belongs to class 4

Laser safety: Laser protection class 4 applies to our Wobble manual laser welding equipment when in operation.

PhotonWeld Laser Welding Series = Class 4

This class 4 covers most powerful and dangerous lasers

Class 4 lasers can cause permanent eye injury through either direct exposure or reflected light.

They can also burn the skin and cause fires.

All lasers used in welding industry, surface cleaning industry and metal cutting industry are Class 4.

Different measures are therefore required on the customer side to ensure laser safety, such as:

=>the appropriate training of employees,

=>wearing special protective equipment and

=<setting up a separate laser safety area.

EYE AND SKIN DAMAGE

Laser system eye and skin hazards are addressed in the laser safety standards. In many use situations, special laser eye protective devices are required. According to the safety standard, this eyewear must be labeled with both the optical density (protective factor) and wavelength(s) for which the protection is afforded. The protective eyewear must be compatible with the manufacturer’s specifications for the laser system in use, to ensure that the eyewear is suitable. In addition to the primary hazard of the laser beam, there may be a considerable eye hazard from high levels of secondary radiation. The safety standard requires that the eyes be protected from this secondary radiation in addition to the primary laser beam. A precaution must be added here—standard safety glasses alone do not provide protection. Any laser eyewear, plain or prescription, must be labeled with the wavelength(s) of protection and the optical density at that wavelength(s). In some laser systems, infrared light may be leaked into the workplace. Thus the eyewear should provide primary beam protection, secondary radiation protection, and also infrared protection.

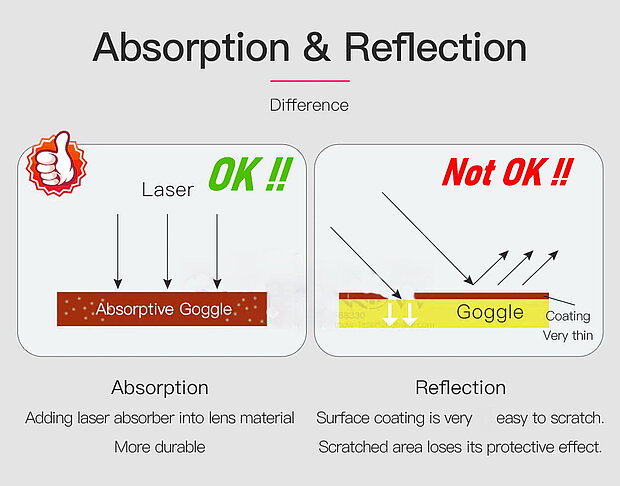

Never use surface coated protection Glasses

Every little scratch in the coating let full acces to your eye for the dangerous laser light!!

Use only in fully Mass tinted glasses, with fully protection in the glasses itself.

Never use surface coated glasses as the slightest scratch in the tiny surface coating makes your glases unsafe and not more usable for laser welding!

Don't let your eyes destroy by cheaper but coated safety glasses!!

Download our special on Laser welding eyes protection

Get our Laser Welding Eyes protection special

Lasermach laser welding protection glasses - laser welding protection goggles - laser welding protection face shields - laser welding protection helmets - laser welding protection for eyes

GOTO our Download page to download the manual and price list

Rules of conduct on the safe use of lasers

The following rules are of particular importance:

- Never point the laser beam at anyone’s eyes!

- Do not look directly into a laser beam!

- Always wear protection glasses!

- If the laser light accidentally strikes your eyes,

- close your eyes and immediately move your head out of the laser beam.

- Do not use any focusing optical device to look at the laser beam while working with lasers.