PhotonWeld © - the new reference in real sustainable handheld and robot Laser Welding

The Best LaserWelding machines for handheld, Robot, Cobot, automation and CNC machines

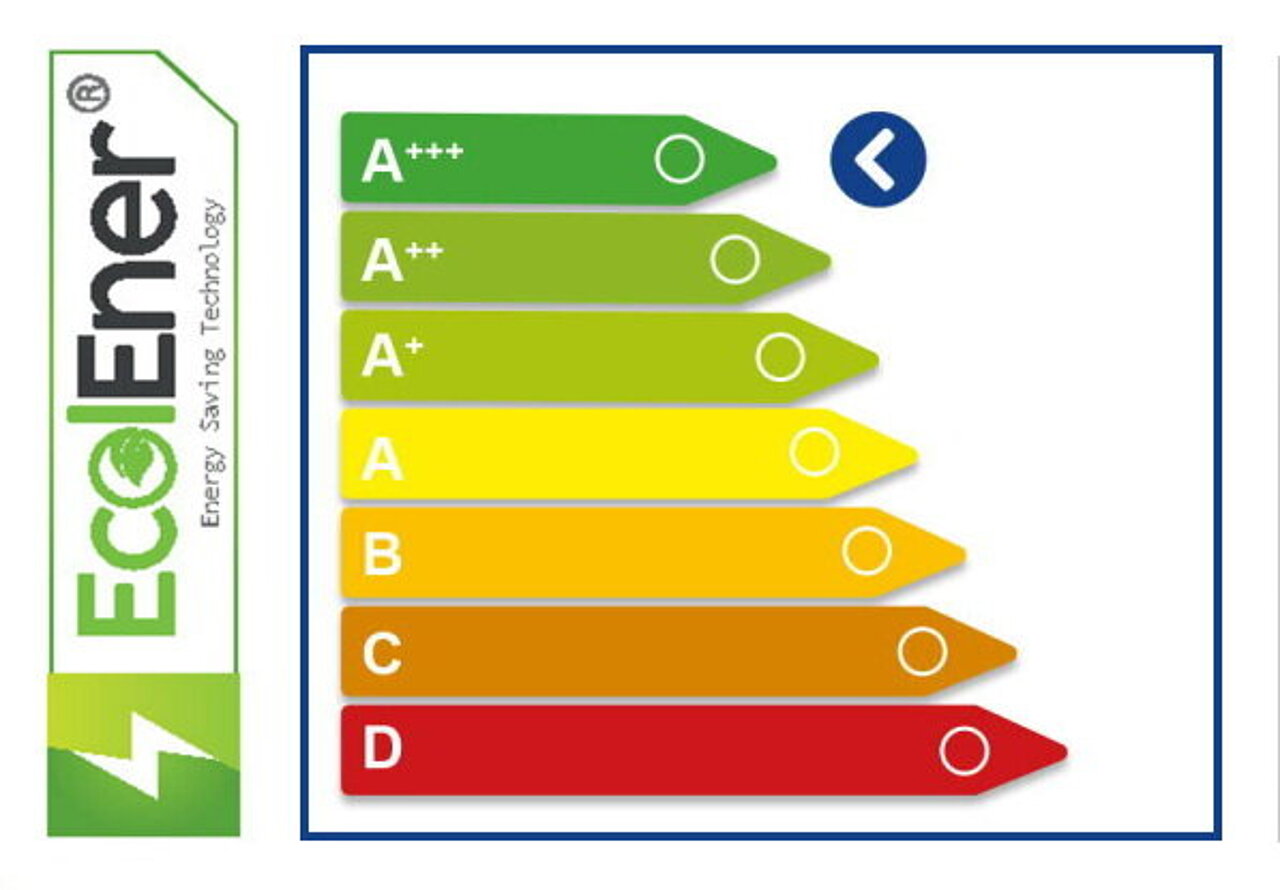

EcolEner : patented High Efficient Energy saving Technology from Lasermach

Saving minimal 22% energy compared to laser welding machines with standard laser sources

Sustainability is emerging as an important approach that manufacturing companies employ to improve their economic profitability and competitive advantage by enhancing environmental performance. Consistent with the contemporary aspects of ecological responsibility, specific forms of ECOLogical ENERgy (ECOLENER ®) saving mediate the relationship between an environmental sustainability orientation and environmental performance.

Every PhotonWeld laser Welding Machine is equipped witht the unique and patented EcolEner energy saving technology. Minimal 22% energy saving compared to any other laser source and up to 85% energy saving compared to any other Welding Machine

EcolEner ®: Sustainable ECOLogical ENERgy Saving Technology for Lasers

Rethinking Welding for a Greener Tomorrow

Currently, the metal welding sector accounts also for of part of global carbon emissions. According to experts, this number is expected to increase dramatically by 2030, which leaves a clear incentive for the industry to deliver significant reductions in emissions in the years to come. With our New PhotonWeld© High Efficient Laser Welding Machine with the revolutionary EcolEner® Energy Saving Technology, we are able to increase the Wall Plug Efficiency to levels over 50%, which is an energy consumption reduction of over 22% to 35% compared to normal laser welding machines.

EcolEner ®: Sustainable ECOLogical ENERgy Saving Technology for Lasers

ECOLENER ® Photon Saving Technology

Huge reduction on CO2 production by switching to PhotonWeld

Normal arc welding produces 9.82 grams of CO2 per second

PhotonWeld laser Welding produces 1,57 gram CO2 per second

or

84% less CO2 PRODUCTION by PHOTONWELD Laser Welding

PhotonWELD uses the new EcolEner High Efficiency Laser Source family

Lasers with record wall-plug efficiency of almost 50%.

PhotonWELD uses the new EcolEner High Efficiency Laser Source family, a new generation of kW class low-mode Ytterbium fiber lasers with record wall-plug efficiency of almost 50%. PhotonWELD Series offers an unparalleled level of reliability, have higher wall-plug efficiency, are brighter and more reliable than kW class diode lasers built by combining multiple emitters into a single output. The ECOLENER Series is perfectly suited for applications that cannot tolerate any downtime or service intervention. The EcolEner can be used in all high power application areas, including cutting, welding, brazing, cladding and surface treatment.

PhotonWeld© with EcolEner© Technology

The Best and most ecological LaserWelder on the market today

Our proven EcoLener © family of very high effiencient lasers is a new generation of kW class high brightness Ytterbium fiber lasers with record wall-plug efficiency of almost 50%. Lasermach's EcoLener series offers a new, unparalled level of reliability. The EcoLener series is perfectly suited for applications that cannot tolerate any downtime or service intervention. PhotonWELD laser Welding Machines with EcoLener high Efficient Laser Sources mark another ‘first’ for the company, in providing the highest efficiency, most reliable industrial lasers available.

PhotonWELD © enhances Lasermach’s corporate sustainability programs as it is designed to enable a more environmentally friendly welding process offering very low electric consumption, low fume generation, low noise operation, and a drastic reduction of consumables, post processing clean up and reduced scrap disposal.

EcolEner ®: Sustainable ECOLogical ENERgy Saving Technology

ECOLENER ® Laser Power Saving Technology

Sustainability is emerging as an important approach that manufacturing companies employ to improve their economic profitability and competitive advantage by enhancing environmental performance. Consistent with the contemporary aspects of ecological responsibility, specific forms of ECOLogical ENERgy (ECOLENER ®) saving mediate the relationship between an environmental sustainability orientation and environmental performance.

EcoLener Laser Source: Wall-plug Efficiency of almost 50%

Big Energy saving for a Greener future

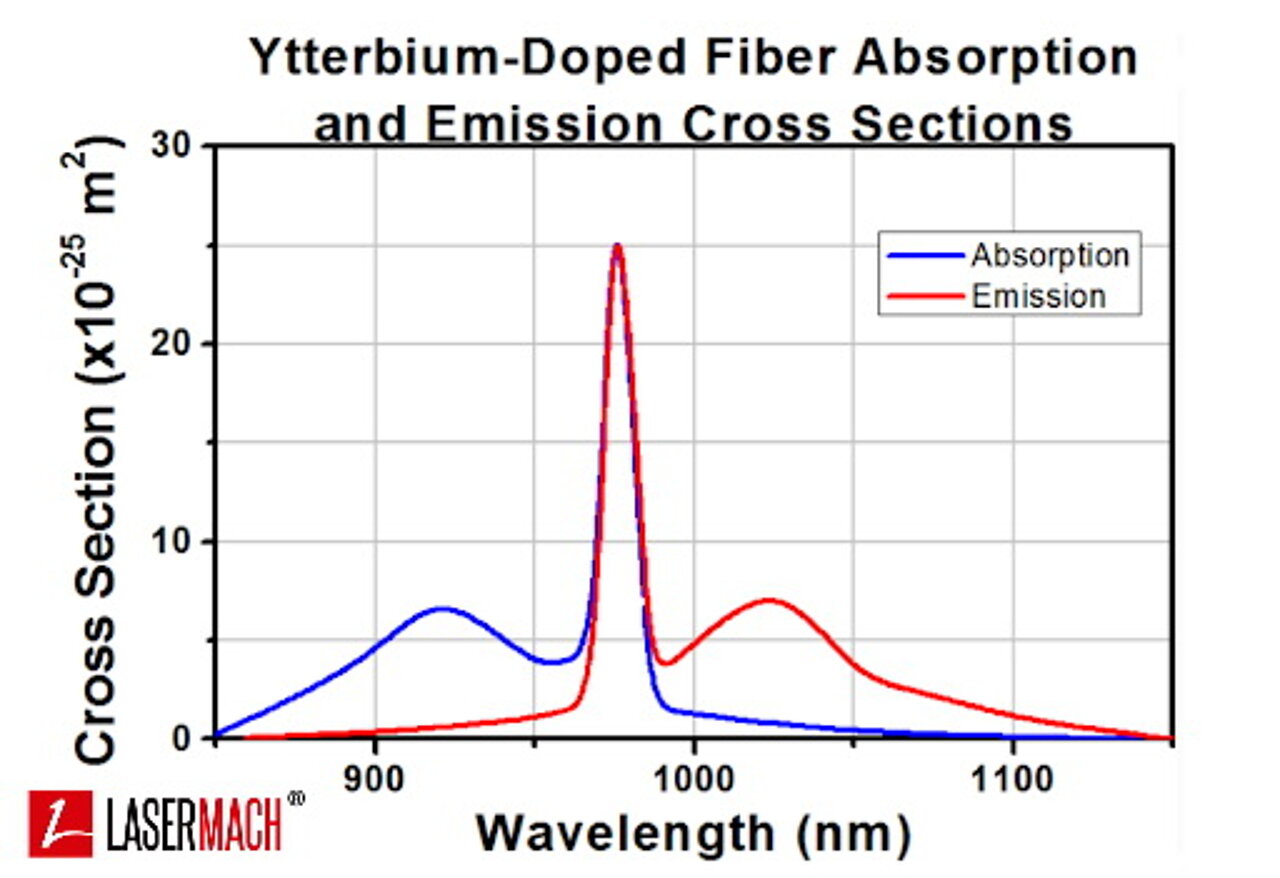

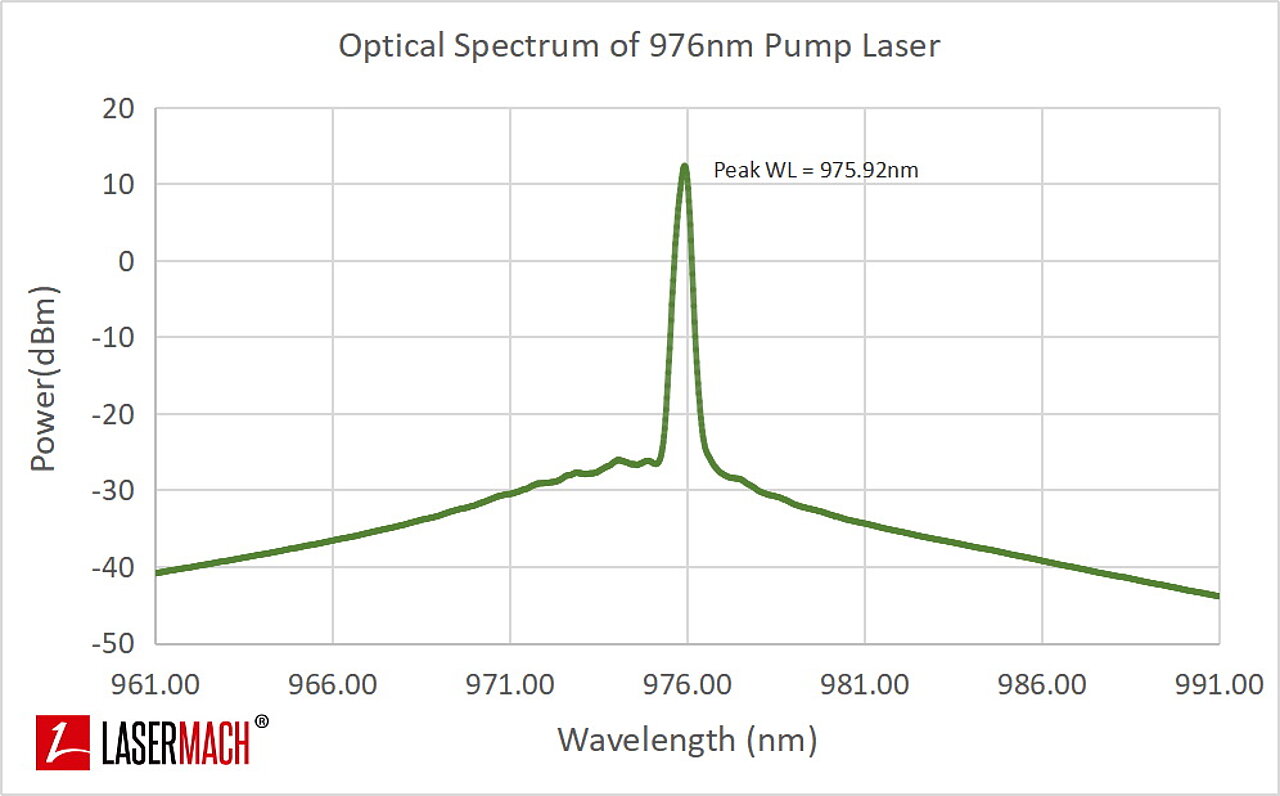

976nm pumped fiber laser achieves 85% optical efficiency

The 976nm pumping solution has obvious advantages and will gradually become the mainstream of the market.

The current laser welder equipment in the market are mainly water-cooled solutions, that is, heat is taken out of the laser through the external circulation of the chiller. Lasermach's PhotonWeld focuses on continuous discussion and innovation based on 976nm technology, combined with the high photoelectric conversion efficiency of 976nm Creatively solved the problem of air-cooled refrigeration capacity, launched the air-cooled 976nm technology for the first time in the industry, solved the power consumption and portability issues, and once again lead the technical development direction of fiber lasers.

The 976nm semiconductor laser is applied to the high-power fiber laser in the industrial market. Due to the elimination of the nonlinear effect of the fiber, nearly 85% of the light-to-light conversion efficiency is achieved, the whole system is weakly affected by the ambient temperature, and the reliability of the semiconductor laser itself is higher. Many advantages will be more and more valued and welcomed. In the long term, with the scale application of the 976nm fiber-coupled module, it is believed that the product technology level will continue to improve, and low-cost 976nm wavelength locking on components will become a reality.

The 976 nm chip is more reliable than the 915 nm chip and has a longer life expectancy!

The 976nm semiconductor laser pump source as a core device also improves the reliability and life expectancy of the fiber laser machine.

As far as the semiconductor laser itself is concerned, the 976 nm chip is more reliable than the 915 nm chip and has a longer life expectancy. Although the GaAs epitaxial crystal material has a slightly better photoelectric conversion efficiency in the 915 nm, the photon energy is lower due to the longer wavelength of 976 nm, and the cavity surface damage threshold of the high-brightness semiconductor laser chip under high current operating conditions is improved. In other words, the 976nm chip has a lower probability of cavity surface optical catastrophic damage (COD) than the 915nm band chip, and the chip itself is more reliable. Therefore, the 976nm semiconductor laser pump source as a core device also improves the reliability and life expectancy of the fiber laser machine.

In the past, the 976nm pump source was applied to industrial fiber lasers, and the whole machine was greatly affected by the ambient temperature.

In the research market, the use of 976nm to develop high-power or even megawatt fiber laser applications has been relatively mature. In the industrial market, the development of high-power fiber lasers by the 976nm pump source has just begun to spread.

In the past, the main reason for restricting the industrial application of 976nm pump source is that the absorption peak of the gain active fiber in the 976nm is narrow: when the temperature of the working environment changes, the drift of the center wavelength of the pump source causes the absorption rate of the gain active fiber to change greatly, which is easy. This leads to fluctuations in the performance of the fiber laser. The industrial use environment is complicated. In the past, low-power fiber lasers used air-cooling to cool the pump source, and the temperature control capability was limited. As a compromise, developers are actively or forced to use the 915nm with a wide absorption peak but lower absorption efficiency to reduce the impact of ambient temperature changes on overall machine performance. The 976nm pump source with VBG wavelength locking is generally used for scientific research purposes due to high cost, and large-scale industrial promotion is not accepted.

EcoLener 976nm: The new Green Number

Our EcoLener 976nm pumped high efficient fiber laser Sources achieves 85% optical efficiency with a Wall-Plug efficiency of almost 50%, which is much higher than any other wobble laser Welding Machine

Ecologic 974nm laser technology: EcoLener Technology

Now,there are no technical barriers to the application of the 976nm pump source to high-power fiber lasers, and the solution has been validated in batches.

Due to the higher light-to-light conversion efficiency in the 976 nm, the laser has less heat rejection, and in fact the system thermal management pressure is smaller.

The difference is that high-power fiber lasers basically use industrial water-cooled machines for forced water circulation refrigeration. Even with non-wavelength-locked 976nm pump sources, the cooling power, temperature control level and cost of existing water-cooled machines have fully met the requirements of fiber lasers. Pump source temperature control requirements. Due to the higher light-to-light conversion efficiency in the 976 nm, the laser has less heat rejection, and in fact the system thermal management pressure is smaller.

After years of application demonstrations at several third parties, it shows that the high-fiber laser in the industrial market uses the non-wavelength-locked 976nm pump source.

There is no technical and cost application obstacle, and the ambient temperature is on the whole system.

The performance impact is weak and controllable, and it has a strong competitive advantage in cost performance.

The advantages of fiber laser with 976nm laser pump technology

During the past decade, with the continuous improvement of pump source and laser structure, fiber laser technology has greatly improved. Based on the doped optical fiber (YDF-Laser) is widely used in industrial, scientific research, etc. because of high electrical-optical conversion efficiency, better beam quality and stability.

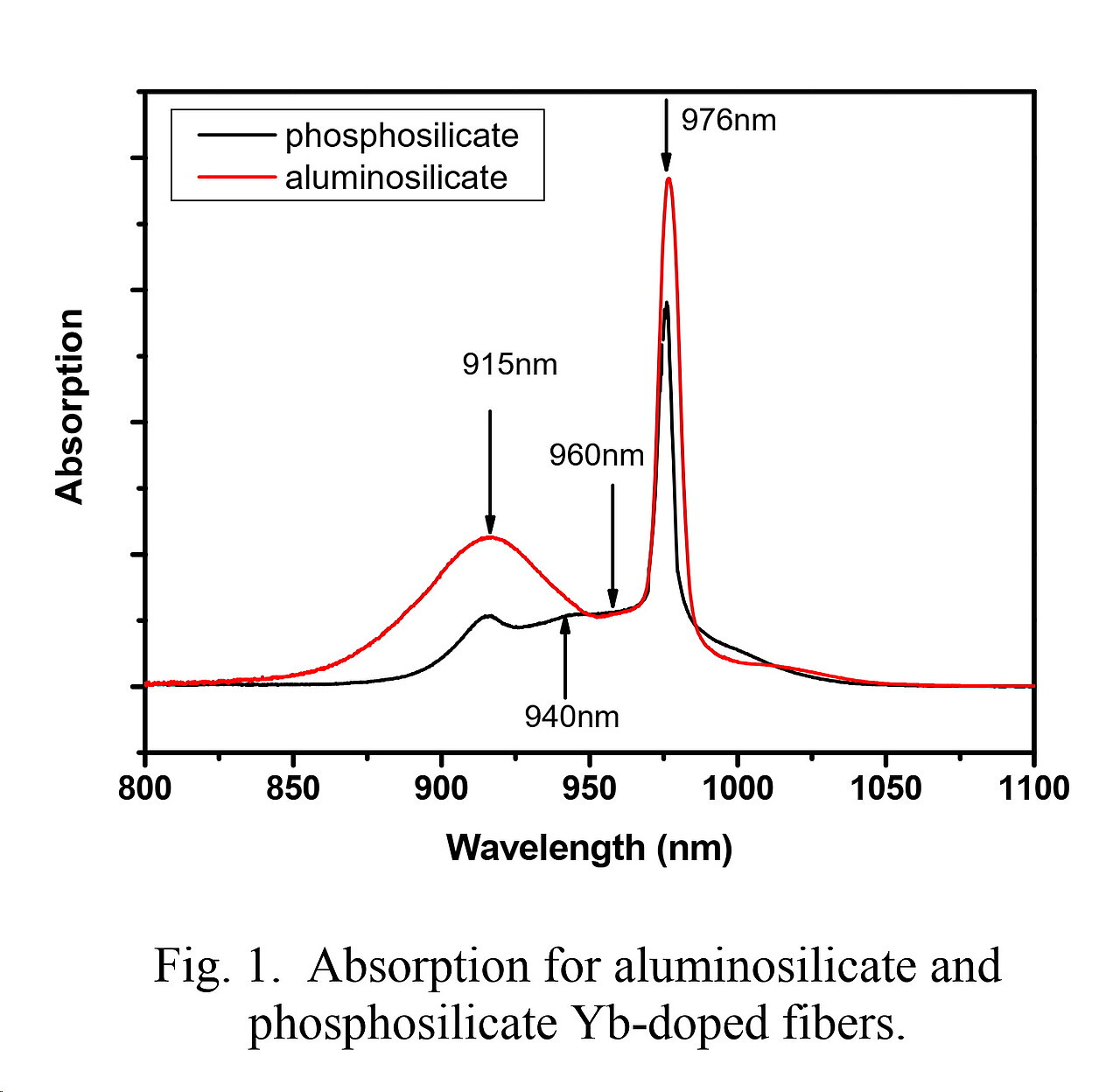

From this picture you will notice that 976nm wavelength absorption peak value is almost 3 times of 915nm absorption peak value. 976nm pump technology is with a much higher efficiency. At the same time, higher absorption also means effectively reduce the length of the fiber, thereby limiting harmful nonlinear effects to a certain extent.

ECOLENER laser series electrical-optical conversion efficiency up to 48% and the optical-optical conversion efficiency of 976nm pump technology up to 87%, the 915nm pump technology only up to 72% meanwhile , high efficiency means lower electricity consumption.

Based on 976nm pump technology, with a 10kW fiber laser will be saving 100,000 Euro during all life time compared 915nm pump technology 10kW fiber laser .