Laser Welding fumes

In an environment where hazardous fumes are used, the protection of welders has always been of great importance. Many countries tighten their legislation every year. This is not without reason, as the health effects of welding fumes can range from poisonings to chronic diseases and more.

Lasers are now an essential tool in industry for cutting, marking, engraving and welding a vast range of materials. A variety of toxic fumes and particulates are generated when different substrates are being laser welded. The majority of which is less than 5µm (microns) in diameter. These contaminates are known within the industry as LGACs (Laser Generated Air Contaminates).

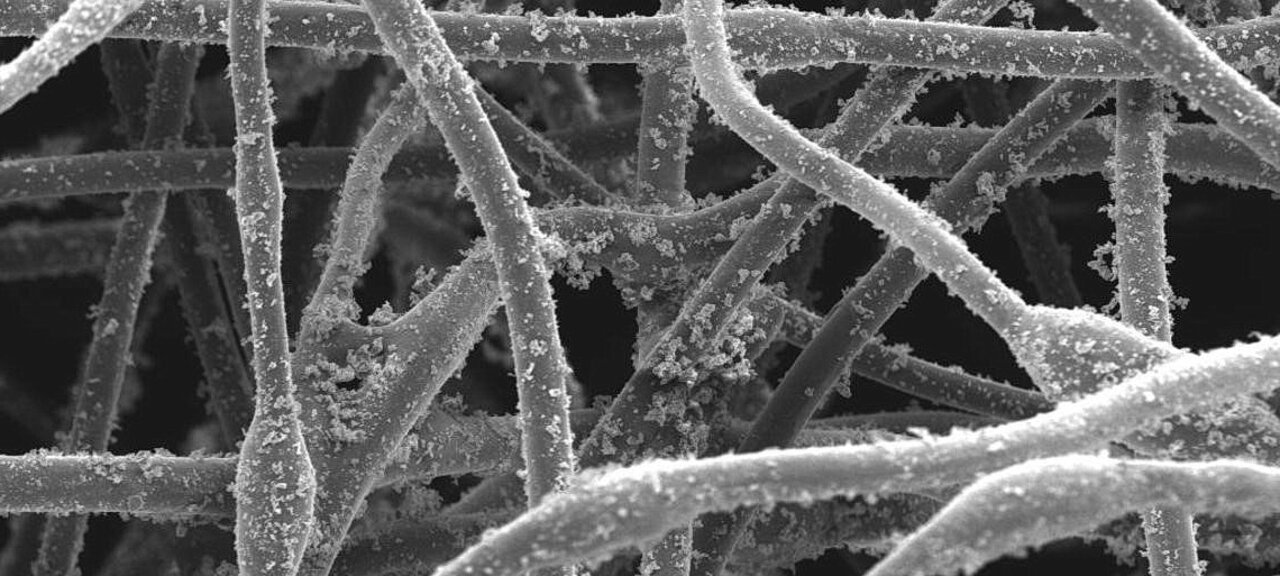

Welding fumes consist of very small particles and even more nano-particles. These can penetrate deeper into the lungs and body, making them the most harmful.

There are three main areas of consideration associated with the laser welding fume:

- Health issues - the effects it may have on the workforce coming into contact with it

- Laser efficiency - the effects on the laser optics.

- Product contamination - the effects on the products being laser welded

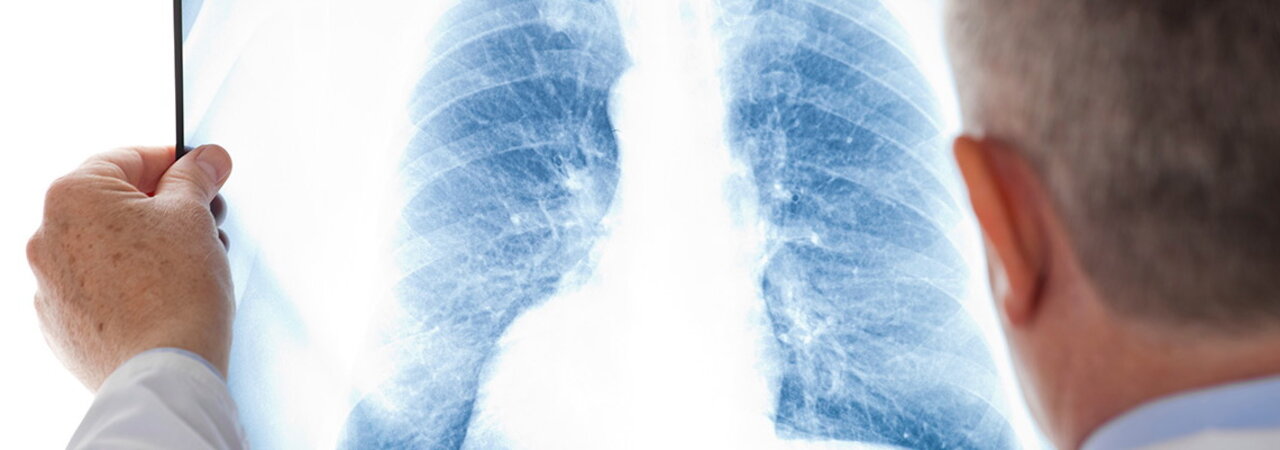

These fumes or particles fall within the respirable range and need to be removed from the working environment to prevent bronchial or lung damage. Most companies only offer a filter for the larger particles, but you need also need an optional special filter for the smallest harmful particles when using Laser welding.

Welding fume is a known carcinogen that can lead to lung cancer, according to the International Association for Research on Cancer

Nowadays, almost every welder is aware that welding fume is toxic. But did you know that it is also carcinogenic?

Fumes are formed when a metal is heated above its boiling point, and its vapours condense into very fine particles. Their size ranges from 0.005 to 20 µm, but most are smaller than 1 µm and may deposit throughout the respiratory system.

According to a publication from the International Agency for Research on Cancer (IARC), welding fumes are a group 1 carcinogenic to humans. In addition, the American Conference of Governmental Industrial Hygienists (ACGIH) has classified multiple substances found in welding fume as carcinogenic.

Potential cancer-causing agents found in welding fume

Welding fume is now considered a known carcinogen that can lead to lung cancer and is classified as a group 1 carcinogen, the agency’s designation for agents carrying sufficient evidence of human carcinogenicity. According to a publication from the International Agency for Research on Cancer (IARC), welding fumes are a group 1 carcinogenic to humans. In addition, the American Conference of Governmental Industrial Hygienists (ACGIH) has classified multiple substances found in welding fume as carcinogenic.

Here is how they classify metals and gases commonly found in welding fume:

| Arsenic | A1 | Aluminium | A4 | |

| Beryllium | A1 | Chromium (III) | A4 | |

| Chromium (VI) | A1 | Iron Oxide | A4 | |

| Cadmium | A2 | Manganese | A4 | |

| Cobalt | A3 | Nickel (soluble compound) | A4 | |

| Lead | A3 | Nitrogen dioxide | A4 | |

| Molybdenum | A3 | Ozone | A4 | |

| Titanium dioxide | A3 | Nickel (metal) | A5 | |

| Vanadium pentoxide | A3 |

- A1 = Confirmed human carcinogen

- A2 = Suspected human carcinogen

- A3 = Confirmed animal carcinogen with unknown relevance to human

- A4 = Not classifiable as a human carcinogen

- A5 = Not suspected as a human carcinogen

⇥ Arsenic (A1) is used to manufacture alloys, generally lead or copper. It can sometimes be found in welding fume and is classified as a confirmed human carcinogen.

⇥ Beryllium (A1) can be found in welding fume as it is used as a hardening agent for copper, nickel, magnesium, and aluminium alloys, as well as for electrical contacts (high heat capacity). It is a confirmed human carcinogen and one of the agents causing metal fume fever.

⇥ Hexavalent chromium (A1) can be found in fumes when welding most stainless steels and high-alloy materials. Chromium is also used in the composition of welding rods or as a plating material. It is converted to a hexavalent state by high temperatures. Hexavalent chromium is a known carcinogen for humans.

⇥ Cadmium oxides (A2) can be found in welding fume as some stainless steels and zinc alloys contain cadmium. It is also used in coatings and plating. Cadmium is also present as an impurity in non-ferrous metals (zinc, lead, and copper), iron, and steel. It is classified as a suspected human carcinogen.

⇥ Cobalt, Lead, Molybdenum, Titanium dioxide, and Vanadium pentoxyde are classified as confirmed animal carcinogens with unknown relevance to humans. More studies will need to confirm the effects on human beings.

EN ISO 16890 standard

Published at the end of 2016, the new EN ISO 16890 standard has established an efficiency classification system of air filters for general ventilation based upon particulate matter (PM). This new classification introducing efficiency for various particle size ranges (ePM 1, ePM2,5, ePM10) provides completely new, so far unavailable opportunities for designing Indoor Air Quality (IAQ). Yet, it differs considerably from the old classification defined in the well-known and commonly applied EN 779 standard.

- PM10: Particles 10 µm in diameter or smaller can reach the respiratory ducts and potentially cause decreased lung function.

- PM2.5: Particles 2.5 µm in diameter or smaller can penetrate the lungs and cause decreased lung function, skin and eye problems.

- PM1: Particles 1 µm in diameter or smaller are most dangerous. They are tiny enough to enter the bloodstream and lead to cancer, cardiovascular diseases and dementia.

Ventilation Solutions needed for Laser Welding

Altough MUCH LESS fume with laser welding, you still need fume extraction!

Laser welding is a rapidly growing process in manufacturing and is popular due to its high level of precision and efficiency. While the initial investment for laser welding systems is higher than most other systems, the benefits are profound in terms of ability and speed.

However, laser welding operations incur serious challenges when it comes to weld fumes. Because laser welders operate at such high temperatures, their weld fumes, altough much less than in normal welding, are full of very small particulates. The smaller the particulate, the more inhalable and dangerous it is for workers.

While a laser welder functions in an enclosed cell—one without a human operator—it is still very important to capture the fumes inside the cell. Besides toxicity and other reasons to collect weld fumes, such as safety regulations, laser welders need a fume free environment so the laser can perform at its optimal level. If fume builds up near the laser, the particles within the fume can refract the laser beam, making the process both less efficient and less precis

Exposure Risks for Laser Welding Dust and Fume

In some ways, laser welding is a much safer metalworking process than many others. Sure, there is a high-powered laser involved, but the process is fast and hands-off. However, the dust and fume created by laser welding can be a serious inhalation hazard. The intense heat involved in the process creates particulates in the sub-micron size; the smaller the particulate, the easier it is inhaled and absorbed into the body.

Because metal welding produces metallic dust, the process is especially dangerous. Dusts might include metals such as chromium, lead, nickel, cadmium and others. These dusts are so dangerous the Occupational Safety and Health Administration (OSHA) has issued separate worker exposure limits for each one. Some of these metals have been implicated in cases of cancer and other serious diseases.

Fine metallic dusts can be an ignition hazard, as well. If certain metallic dusts accumulate in an enclosed space and interact with water, they can produce hydrogen and lead to an explosion. Dust explosions injure or kill many workers, every year.

Laser welding fume causes other problems, as well. While not a health issue, the impact of fume on cutting efficiency is a serious concern. Fume from laser welding can be so thick but invisible for our eyes, that it can diffuse the beam. This reduces the intensity of the beam and can interfere with the process. Also, maintenance costs for these processes can rise if dust is not extracted properly.

Depending on the materials being welded, laser welding may generate fumes that are hazardous to health.

Altough laser welding generates much less fume than any other welding process

Therefore, it is important to always provide sufficient extraction and fresh air.

Given the possible automation of laser welding units, the systems can achieve much higher productivity than a strictly manual workforce while consuming less resources. The downside of this increased efficiency is additional weld fume and the need for capture equipment to effectively remove the smoke from the area. Lasers, after all, require a very clean operating environment since smoke causes laser refraction and refraction is the enemy of good welds.

Laser welding fume extraction requires a slightly different approach than typical manual welding ventilation systems. As stated above, the lasers require an extremely clean air environment to protect against laser refraction which can result in an indirect focus of the light beam on the weld seam, diminishing quality. The laser welding ventilation system should provide a 10 to 15 second turnover rate for air at the point of welding to ensure a clean enough environment.

In addition to a clean air environment, laser welders require light-tight enclosures to prevent lasers from escaping the weld area and causing harmful effects to the plant and workers. Since the enclosure is essentially sealed, source capture welding ventilation systems should be integrated to each laser welding enclosure to prevent weld fume accumulation.

Finally, it's important to remember the characteristics of weld fume particulate created in laser operations. Compared to other types of welding, the resulting particles are much finer. Therefore, the laser welding ventilation system should incorporate filters designed specifically for capturing these ultra-fine particles and removing them from the air before it's returned to the plant environment.

Air emissions from welding: radiation, fumes, dust

Danger of Welding emissions

Depending on the materials being welded, laser welding may generate fumes, altough much less than any other welding process, that are hazardous to health.

First of all, we need to talk about the most dangerous emissions into the atmosphere from welding, both for professionals and for those who use the finished product: Welding fumes.

This Welding fumes, although in very little quantities produced at laser welding, are a very different problem: the effect changes according to the welded metal, going from problems with the respiratory system to damage to the skeletal system. For this reason, during welding, the work area must be well ventilated, or equipped with the right suction machinery.

Another element that requires suction are the so-called welding powders, very small particles of material with high toxicity and capable of penetrating the respiratory system. Electrode welding has the highest concentration of dust among all welding techniques, so you need to protect yourself with a mask

Therefore, it is important to always provide sufficient extraction and fresh air.

Indoor Air Quality (IAQ) Impact on health

IMPORTANCE OF AIR FILTRATION

The effects of particulate matter on human health have been extensively studied in the past. The results are that fine dust can be a serious health hazard. The most important diseases which have been associated with (caused or aggravated by) indoor air exposures due to PM contamination are:

- Allergy & Asthma

- Lung cancer

- Cardiovascular diseases (CVD)

- Chronic obstructive lung disease (COPD)

- Dementia

What are laser welding fumes?

Laser welding fumes are a complex mixture of metals metallic oxides, silicates and fluorides. Fumes are formed when a metal is heated above its boiling point and its vapours condense into ultrafine particles (solid particulates). Laser welding fumes generally contain particles the materials being welded. Make sure you remove other coatings like plastics, paints, rubbers, greases, and oils as these may increase the risk fires and/or create other unwanted toxic gases.

For example:

- fumes from laser welding mild steel contain mostly iron with small amounts of additive metals (chromium, nickel, manganese, molybdenum, vanadium, titanium, cobalt, copper etc.).

- Stainless steels can have larger amounts of chromium, including hexavalent chromium, or nickel in the fume and lesser amounts of iron.

- Nickel alloys have much more nickel in the fume and very little iron.

- Contributions to the fumes can come from coatings on metal being welded. Some ingredients in coatings can have toxic effects. These ingredients include: Zinc on galvanized steel (vaporizes to produce zinc oxide fume, cadmium plating, and chromates. These also form ultrafine particles.

Moreover, there is good evidence of the effects of exposure to various particle size ranges:

Typical particulates found in air/fume include:

- Coarse particles, often 10 microns (μm) or bigger (1µm = 1/1,000th of a millimetre). Examples include visible coarse dust, sand, leaves, hairs and other large organic particles.

- PM10 – airborne particles =/< 10µm in diameter including coarser fine dust and organic particles.

- PM2.5 – airborne particles =/< 2.5µm in diameter such as pollen, spoors and other organic particles.

- PM1 – airborne particles =/< 1µm in diameter, including dust, combustion particles such as diesel fumes, bacteria and viruses.

Poor air quality results from particulate matter (PM) in the air. PM comprises a complex mixture of solid and liquid particles of organic and inorganic substances suspended in the air. Its major components are sulphate, nitrates, ammonia, sodium chloride, black carbon, mineral dust and water. PM has both physical and chemical characteristics, man-made and natural sources that vary by location. It should be noted, however, that people will react differently to poor quality air, depending on their sensitivity.

The human body can filter coarse particles.

PM10 particles can be stopped as they enter the throat. PM2.5 particles are dealt with in the lungs and alveoli. PM1 however, penetrates into the bloodstream and can contribute to serious illness. At worst, PM1 can contribute to deadly diseases like heart attacks, lung cancer, dementia, emphysema, Oedema, and other serious diseases, leading to premature death.

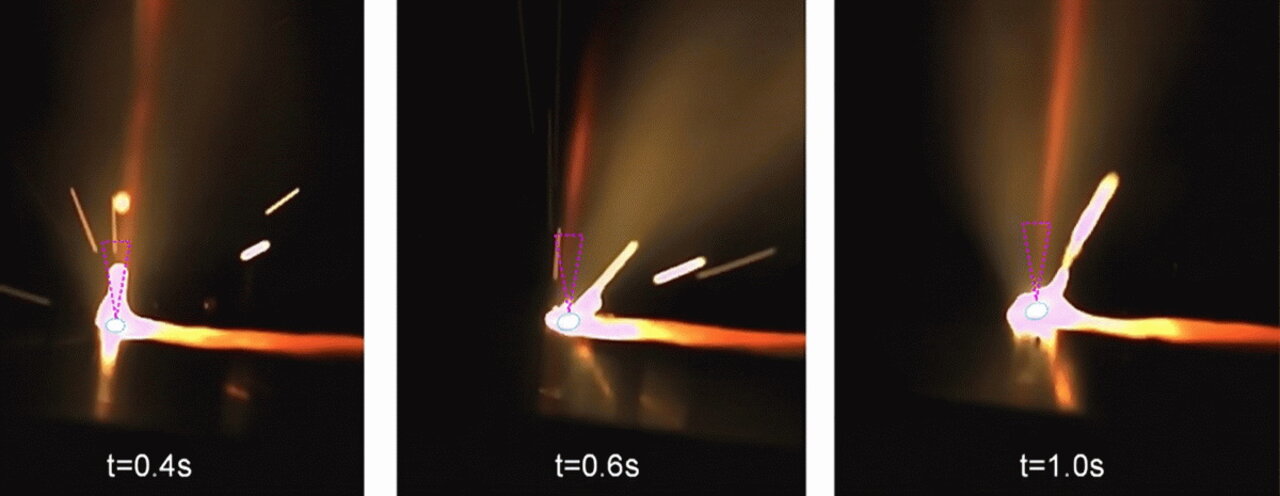

Although invisible for the human eye, there is a fume creation which can influence our health

Infra red picture of the laser welding beam creating invisible fume

The Dangers Of Hexavalent Chromium In Welding

When it comes to industrial welding, toxic gasses and fumes can not be avoided. Of course, prolonged exposure to these can create respiratory problems, illnesses, and even death. Fortunately, with the right fume extraction equipment, you can mitigate the dangers of these gasses. But one toxin in particular to look out for is something called hexavalent chromium.

What Is Hexavalent Chromium?

Hexavalent chromium is chromium converted to a valence state. This gas occurs naturally as a byproduct of industrial processes. When alloy steel is combined with chromium metals, it can increase its longevity.

However, this also creates a threat in the air around the workspace. This can severely affect human health. It is a carcinogen, and hexavalent chromium can damage the liver, kidneys, skin, and virtually every important system of the human body.

Hexavalent chromium is more common than you think. And it’s important to have the right fume extraction systems in place to reduce exposure to this dangerous substance.

What Does Hexavalent Chromium Cause?

As mentioned, this gas can cause cancer, and exposure to it should be severely minimized. According to OSHA, exposure should be limited to 5 µg/m3 over 8 hours per individual. The reason is, breathing in Hex Chrome can cause illnesses like:

- Nose bleeds

- Difficulty breathing

- Headaches

- Fatigue

- Cancer

- Skin Irritation

- Eye Irritation

Symptoms Of Exposure To Hexavalent Chromium

Symptoms that you or someone has been exposed to this dangerous gas are asthma, nasal perforation, bloody nose, coughing, painful sneezing, irritation of the respiratory system, skin irritation, and eye irritation. If you or anyone has symptoms that may require medical attention, leave the work area immediately. It is possible that this gas or other substances are being breathed in.