Robotic Laser Welding:

The Future of Welding Technology

Robotic laser welding is a highly advanced manufacturing process that combines the precision of robotics with the power of laser technology to produce seamless, high-quality welds. This cutting-edge technology has revolutionized the welding industry, offering numerous benefits over traditional welding methods.

Robotic laser welding combines the precision of robotics with the power of laser technology to produce high-quality welds with accuracy down to the micrometer level. This advanced welding method offers numerous benefits over traditional welding methods, including speed, flexibility, and consistent quality. Robotic laser welding can be used on a variety of materials, including metals, plastics, and composites, making it a versatile solution for a wide range of applications, such as aerospace, medical devices, and consumer electronics. The technology results in strong, durable welds that are free of defects and ideal for use in high-stress environments.

Robotic laser welding is the future of welding technology, offering manufacturers a fast,

precise, and cost-effective solution for their welding needs.

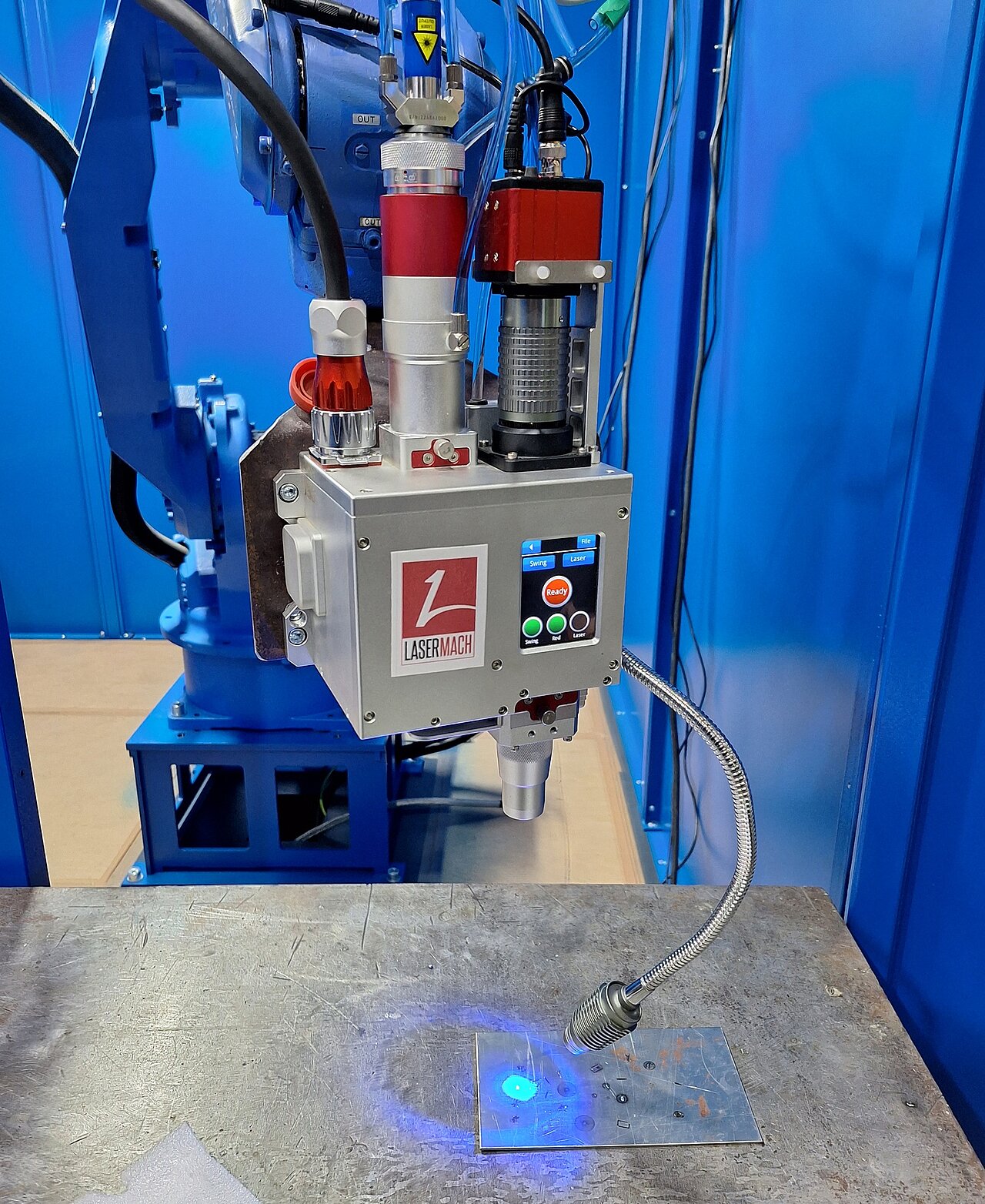

Ready to run Robot/cobot laser Welding Plug-in units

Robotic welding is one of the most common robotic applications in the industrial sector, being driven mainly by the automotive sector for the last several decades. Robotic welding is most productive when completing high-volume, repetitive welding tasks. With the new flexible robots and cobots small batch production and even single part production is in reach of any robot with Wobble-R Fiber laser welding units from Lasermach.

With robotic welding integration, you can:

- Decrease Employee Risk to Burns & Hazardous Fumes

- Increase Quality & Consistency of Welds

- Decrease Time Required to Finish The Job

- Decrease Space Needed to Perform Tasks

- Decrease Labor Costs

with integration of our predefined Wobble-R units, you can:

- Decrease even more Employee Risk to Burns & Hazardous Fumes

- Increase Quality & Consistency of Welds

- Increase drastically the welding speed

- Decrease Time Required to Finish The Job

- Decrease on a huge scale the post processing of your welded parts

- Decrease drastically Labor Costs

- Decrease Heat-affected zone (HAZ)

Significant productivity gains

Lasermach provide full predefined units to replace any conventional welding system on any robot or cobot or automated machine.

Laser welding is an unknown or unexplored option for many manufacturers with automated welding applications, but it is just as easy to implement as other robotic welding systems. The fast travel speeds and low heat input of laser welding makes it especially well-suited for sheet metal welding applications that require precision and attention to aesthetics.

The PhotonWeld R6 laser welding head is designed for high-precision welding applications, including laser welding, laser brazing, and laser cladding (with optional equipment). It features a compact and lightweight design, which makes it ideal for use in tight spaces and hard-to-reach areas.

The welding head is equipped with a range of advanced features that ensure high-quality and consistent welds. These include a high-precision fiber optic laser, which provides accurate and reliable beam delivery, and a gas flow control system that provides optimal shielding gas coverage.

The PhotonWeld R6 laser welding head also features a 360-degree rotation capability (by robot/cobot), which enables the welding torch to move freely in all directions, and a 90-degree tilt function, which allows for easy access to difficult-to-reach welding positions.

In addition to its advanced features, the PhotonWeld R6 laser welding head is also easy to use and maintain. It can be easily programmed and controlled using a central console, and its modular design allows for quick and easy replacement of components.

For operations now using MIG, TIG or resistance spot welding, a switch to laser welding can significantly improve productivity, saving time and money while still producing even better high-quality welds. Implementing our PhotonWeld-R units in your exisiting Robot welding linne is a piece of cake.

The Photonweld R6-Series comes with a full laser unit of standard 1500 Watt aircooled (with heatpump) with maximum welding capacity of 6mm in stainless steel working on 220V Mono . We have two versions : 3kW version and 6kw Version. The unit is plug and play and runs problem free from the first second.

Robot Laser Welding Machine Features

EASY TO OPERATE:

The buttons of the teach pendant are simple and easy to understand,and the teaching programming can be learn and use quickly. lf the operation is wrong, the machine automatically stops to avoid the risk of equipment damage.

WORK EFFICIENTLY:

Once programmed, it can be used all the time. Fortune Laser robot arm supports 24 hours of continuous work with high precision and high speed. Fully automated operation, a robot can complete the workload of more than 2-3 people a day. Traditional welding will be affected by the welding environment and human factors during operation, which slows down the work process and is not conducive to the rational arrangement of production by enterprises. Welding robots have a high degree of automation and can perform continuous operations and long-term welding tasks to help enterprises improve production efficiency.

STABLE WELDING QUALITY:

Stable welding quality is the specific result of a laser welding robot combination: always identical welds with high consistancy in quality. In traditional welding, welding defects such as under welding, partial welding, over welding and so on. Will happen, will increase the material cost of the enterprise. The welding robot can lay down the welding material according to the weld seam, and make full use of the welding material while welding accurately.

LOW COST:

One-time investment, long-term benefits. The service life of Lasermach Laser robotis 80~100.000 hours, which is equivalent to more than10 years of 24-hour uninterrupted work. lt greatly saves labor costs and personnel managementcosts, and solves problems such as difficulty in recruiting people. One operator can operate two to three welding robots at the same time, which reduces the labor cost of the enterprise.

SAFE AND RELIABLE:

A robot cell is equipped with photoelectric safety protection measures. When foreign objects enter the work area, it can automatically alarmand suspend work to avoid accidental injuries.

SAVE ENERGY AND SPACE:

Lasermach automation equipment line layout is simple and tidy, small footprint, no noise, light and strong robot arm, low power consumption, energy saving and environmental protection.

PhotonWeld R-Series Laser Welding units

Replacement units for existing TIG-MIG units an all brands of Robots, cobots and automation!

Easy install and easy use laser Welding units for automated projects

Laser Welding units for automated prouction lines with integrated video setup camera

Precision

Robotic laser welding offers unmatched precision, with the ability to make precise and consistent welds down to the micron level. This level of accuracy is essential for applications in high tech applications, where even small variations can impact the performance and safety of the final product.

Speed

Robotic laser welding is incredibly fast, with the ability to make high precision welds at a speed much faster than traditional welding methods. This speed advantage results in significant time and cost savings for manufacturers, especially when producing high volumes of similar parts.

Quality

Robotic laser welding produces high-quality welds that are consistent and free of defects, reducing the need for post-weld inspections and rework. The resulting welds are also extremely strong and durable, making them suitable for use in high-stress applications.

INTELLIGENT WELDING

ROBOTIC WELDING IS A WORTHWHILE INVESTMENT. AND NOT JUST IN SERIES PRODUCTION!

Faster and more precise welding—this is made possible thanks to our R6 series with various auxiliary systems. In combination with robot control, they all support the welder in their work, helping to make the production process as efficient as possible.

This not only saves time and minimizes errors, it also means that welds can be reproduced in the desired quality at any time—without the need for manual fine-tuning. What’s more, they can withstand the greatest loads and meet the highest demands thanks to their outstanding design.

Our base model PhotonWeld-R has a single robot interface suitable to most of the robot brands.

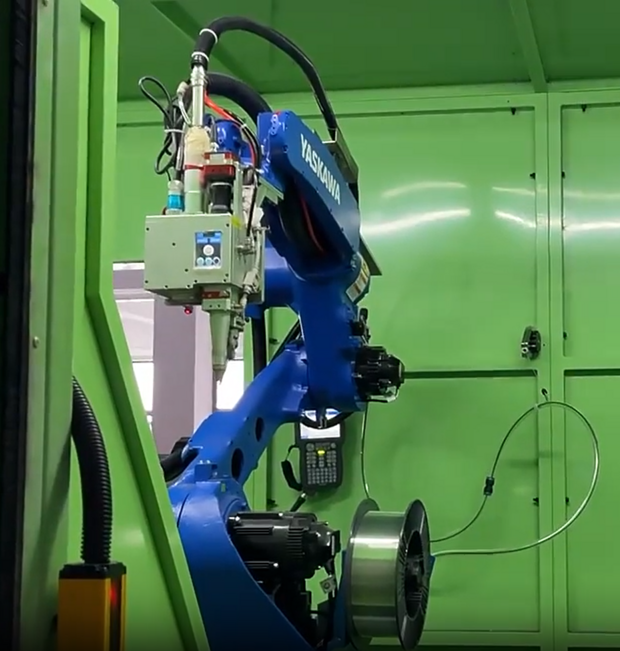

Our PhotonWeld-R units suits following Robot brands

Fanuc Robotics

Yaskawa Robotics

Panasonic Robotics

ABB Robotics

Kawasaki Robotics

Nachi Robotics

Denso Robotics

Kuka Robotics

Mitsubishi Robotics

Epson Robotics

Stäubli Robotics

Foxconn Robotics

Comau Robotics

Omron / Adept Robotics

Universal Robotics

JAKA Robotics

AUBO Robotics

SIASUN Robotics

BORUNTE Robotics

QJAR-EVS Robotics

ESTUN Robotics

Inovance Technology

….

and more

Integrated laser processing equipment, robot system, motion control system, full protective cover, automatic loading and unloading, all in one. We meet all automatic and robotic production needs in the most efficient, safest, fastest and affordable cost. Photonweld fiber laser welding systems are designed for processes up to 6kW source power! Operations are supported by automatic control and visual operating system for easier quality control and production management. Only world class, fully certified components.

Robots and PhotonWeld Laser Welding, the Perfect Fit !

Laser welding, a non-contact joining procedure.

Robotic Laser Welding Cells

Cobotic Laser Welding Cells

Pre-engineered laser welding units for automation

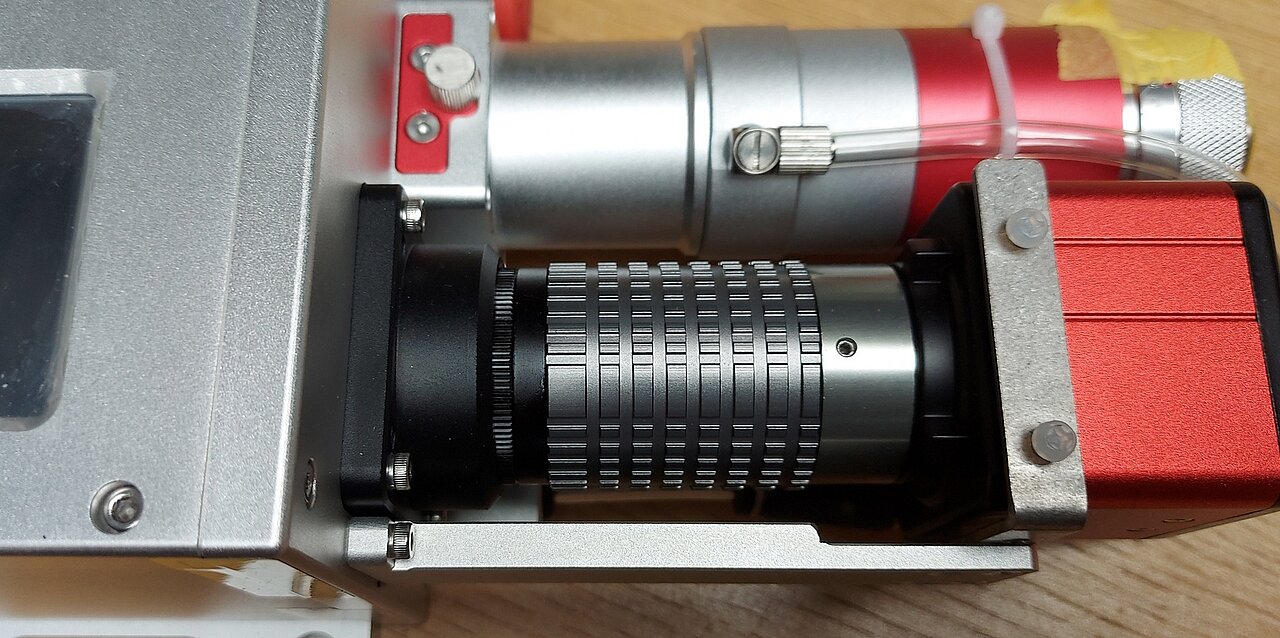

PhotonWeld R-LASER WELDING HEAD

At the heart of the Laser welding system is a compact Laser welding head with an integrated programmable dual axis laser optics. A robot holder connects the Laser head to a standard industrial robot. This gives the PhotonWeld R Laser welding head the flexibility it requires to access difficult-to-reach areas of the workpiece. The welding wire can be placed in any position with respect to the laser beam, enabling the joining process to be adapted precisely to the wide variety of weld-seam preparations, outputs, wire types, wire grades and joining tasks.

Highly integrated 2D scanning galvanometer, controller, optical lens components, etc., the system is stable and reliable, compact in structure, precise in optical path, good in sealing, exquisite in appearance, light in weight and convenient in installation.

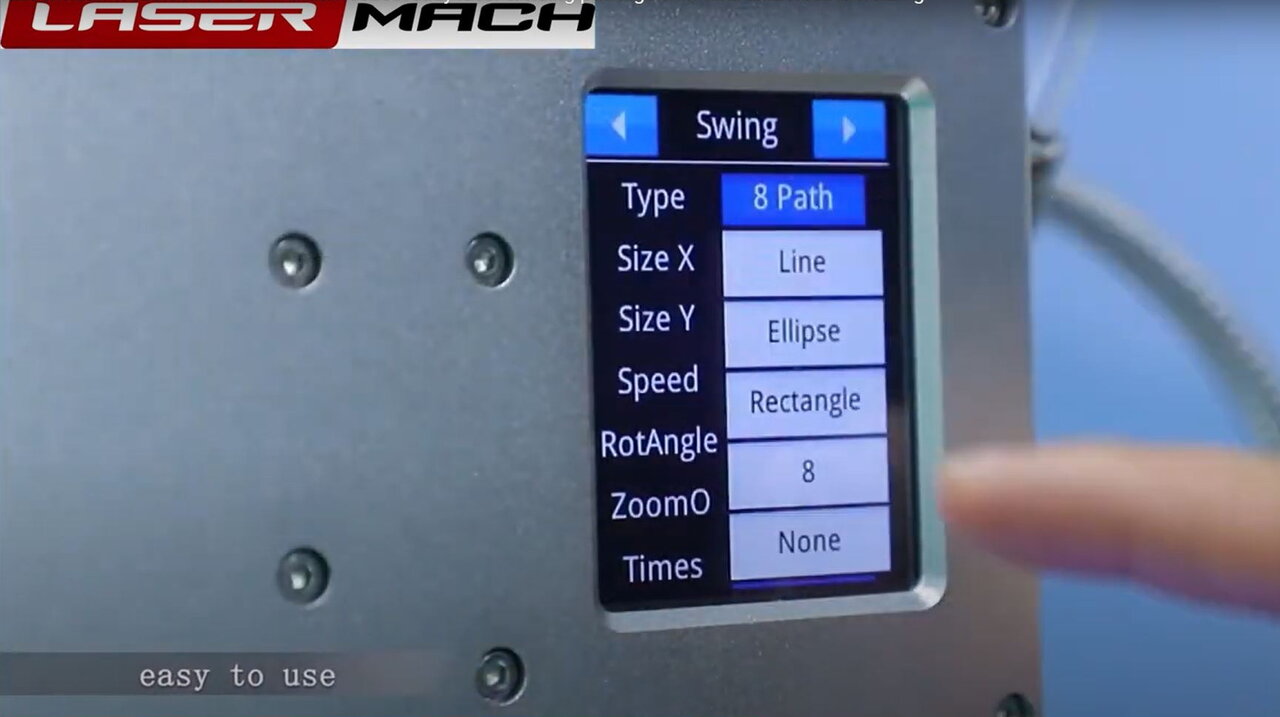

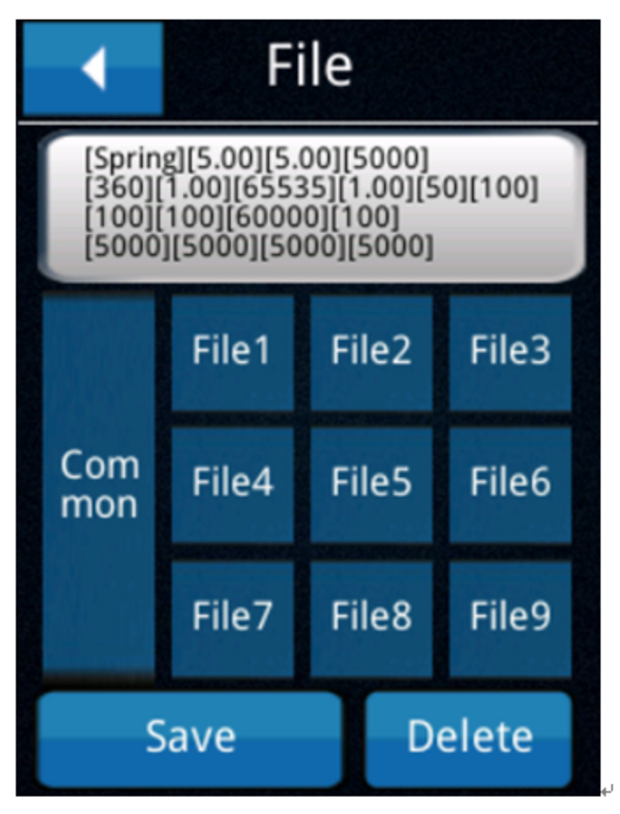

Powerful software:

1. Support linear, rectangle, circle, ellipse, figure 8 and other swing modes, and the length and width of each mode are adjustable;

2. Support rotation, each mode can modify the rotation angle online according to the welding path needs;

3. The 8-character mode supports independent setting of the power on both sides, which supports the user's research and implementation of complex processes;

4. It supports the storage and import of 64 sets of programming parameters, which can be freely combined and used, giving users the flexibility to program different welding paths.

Support for customer remote interface integration:

The laser welding headd can (optional) provide rich interfaces and DEMO development codes, support MODBUS protocol, and support customers to quickly integrate all controls into their own master control software.

Product advantages:

1. With multi-level security protection: support laser alarm shutdown, support online recording of temperature curves in 3 key temperature areas and abnormal alarm shutdown.

2. High welding efficiency: high-speed high-performance scanning galvanometer, high swing frequency, faster welding speed and higher efficiency.

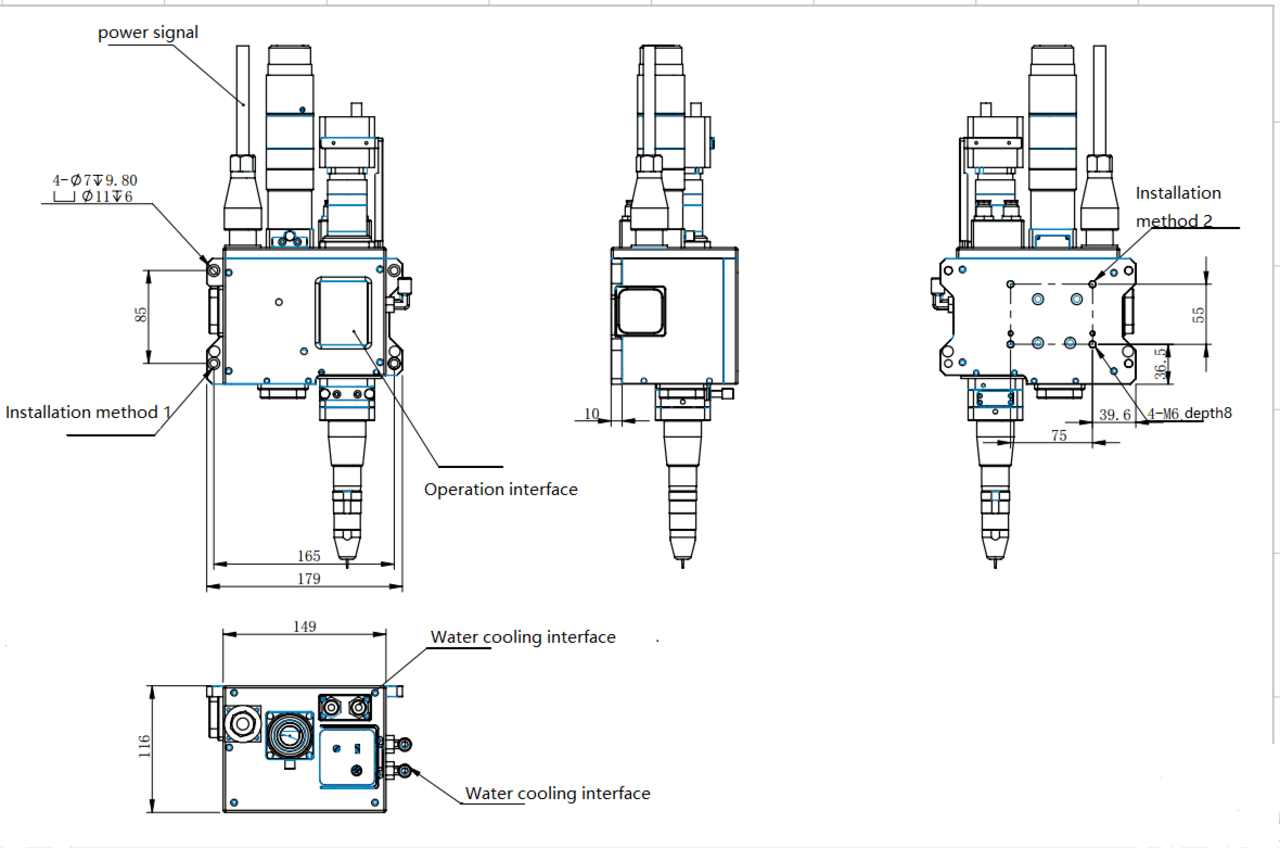

Super easy to install - package fully ready to start - with auto selection of 7 different welding programs

4 Screws, 1 gas connection and 5 relais I/O contacts from robot or cobot to connect, thats all it takes to mount our laser welder on any exisitng or new robot-cobot

Lasermach new product PhotonWeld-R6 high-power wobble welding system is released! It highly integrates high-power two-dimensional scanning galvanometer, control system, human-machine interface, observation camera, QBH, collimator lens, focusing lens and other optical components. It does not need an external controller. It can directly control the galvanometer and laser, and supports external IO triggers to start and supports secondary development of customer remote interface. It can be widely used in high-end processing fields such as laser welding and laser quenching of wide welds. The system is stable and reliable, compact in structure, precise in optical path, good in sealing, exquisite appearance, light in weight and easy to install.

the new PhotonWeld R-6 high-power swing welding system supports linear, rectangular, circular, elliptical, figure 8 and other swing modes, each of which is adjustable in length and width; supports rotation, and each mode can modify the rotation angle online according to the welding path; The mode supports the independent setting of the power on both sides to support the user's research and implementation of complex processes; it supports the storage and import of 64 sets of programming parameters, which can be combined freely, giving users the flexibility to program different welding paths.

The PhotonWeld R-6 can provide a wealth of interfaces and DEMO development codes, support MODBUS protocol, and support customers to quickly integrate all controls into their own main control software. It also supports laser alarm shutdown, online recording of temperature curves in 3 key temperature zones, and abnormal alarm shutdown. It uses high-speed high-performance scanning galvanometer, high swing frequency, faster welding speed and higher efficiency. It will be your better working partner for high-end welding!

Dimensions of our new Wobble6R-PRO+ laser welding head for robot, cobot and cnc

Brand new Wire feeding adjustable bracket for laser welding wire feeding

Our new wire feeding bracket adopts a brand new structural design, with very high tensile strength, good working stability, and more convenient debugging. Both heigth position and infeed inclination are very easy to change and adapt.