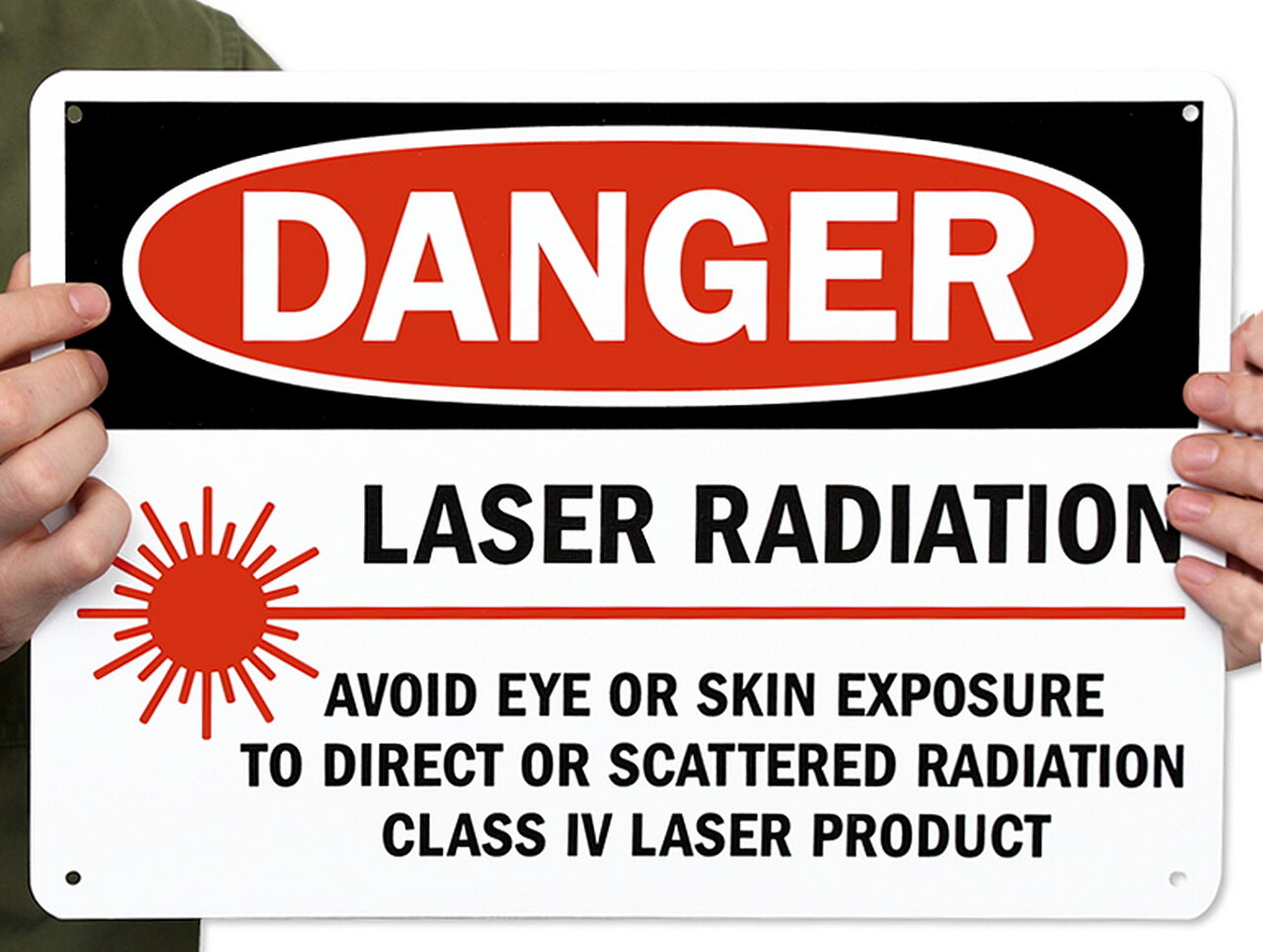

Laser-Augensicherheit: Für unsere manuellen Laserschweißgeräte der PhotonWeld-Serie gilt im Betrieb die Laserschutzklasse 4.

Daher sind auf Kundenseite unterschiedliche Maßnahmen zur Gewährleistung der Lasersicherheit erforderlich, wie beispielsweise die entsprechende Schulung der Mitarbeiter, das Tragen spezieller Schutzausrüstung und die Einrichtung eines separaten Laserschutzbereichs.

Safety for your EYES - EYE PROTECTION

Safety Eyewear for laser Welding

Our Selection of Special Laser Welding protection Goggles and faceshields

Check more on Safety for your Eyes

Safety for your HEALTH - Respiratory protection

Fume Extraction equipment for Laser Welding

Fume extraction is important for keeping your longs clean and healthy

Check more on Safety for your Health

Safety for the Enviroment

Laser Welding Enclosures and cabins for general safety

Safe Working with Handheld Welding lasers, build your own laser welding protected cel

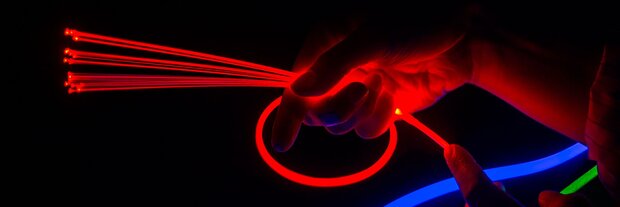

A laser is a device which produces an intense, coherent, directional beam of light.

The term LASER is an acronym for Light Amplification by Stimulated Emission of Radiation. Lasers can be designed to deliver a large amount of energy to a very small area. In laser welding and laser cutting operations, this energy can heat metals quickly to very high temperatures. Much of the radiation that strikes the workpiece can be reflected into the environment, creating hazards. Mostly laser light used in laser welding equipment is invisible for the human eye (INFRARED-A), so the hazard may not be readily apparent.

POTENTIAL HAZARDS of Laser Welding

Laser safety: Laser protection class 4 applies to all our manual laser welding equipment when in operation.

Different measures are therefore required on the customer side to ensure laser safety, such as:

- the appropriate training of employees,

- wearing special Personal protective equipment (PPE)

- setting up a separate laser safety area

SAFETY – WE TAKE IT VERY SERIOUS

You too have to take it VERY serious!

Laser radiation of infrared fibre lasers can cause serious and lasting damage to the human eye – so a handheld laser is not a toy. But simple precautions and our inherent safety design make this a safe solution that meets the requirements of globally active customers and their safety organizations.

Lasermach PhotonWeld© is a Class 4 laser system, requiring:

- Personal protection (laser safety eyewear)

- Safety curtains to block operating area from unprotected bypassers

- Laser safety officer (1 day training)

Lasermach offers superior laser safety:

- CE marking based on an in-depth risk analysis following Machinery Directive EC2006/42/EG.

- a true CE design according to machinery directive EC2006/42/EG

- Components with safety performance level D, including Safety PLC instead of custom control board

- Interface for connection of external safety devices (E-Stop, interlock and laser warning light)

Common Laser Hazards

One aspect to remember about laser welding safety is the variety of hazards associated with the systems which are also prevalent in many other forms of equipment. Basic safety training should mean workers are already familiar with some of these issues, but employers should be aware of:

- intense visible and invisible light

- Compressed gasses

- Intense radio frequency energy

Let’s take a look at each of these individually:

- Some pulsed lasers also utilize a flowing gas design, which requires connection to a cylinder of compressed gas. Most of the gases used for laser systems are extremely safe, though since pressurized cylinders can pose a risk, their transportation and usage should occur only when the cylinders are properly restrained.

- As for radio frequency energy, severe burns can result from the improper servicing of units which use RF generators, such as sealed lasers. Anyone servicing such units should be trained in the unit’s safety procedures, and the connections for RF energy should not be touched during operation.

Light Hazards

Due to the laser engraving safety checks in place for welding systems, units are designed in such a way to prevent operators from coming into direct contact with the laser beam.

One of the issues that can arise, however, involves unintentional reflected light, which falls into the following categories:

- Diffuse Reflections – This type of reflection occurs when a reflective surface’s irregularities create a scattering of light in all directions. Of the types of reflections, this is the safer of the two since energy is being divided in many directions and weakened.

- Specular Reflections – This type of reflection is produced in a way that is more mirror-like, recreating close to 100% of the original light compared to the scattered light of diffuse reflections. Though there is a higher danger associated with this form, it is much less common and laser welding systems are often designed to eliminate specular reflective surfaces that would come across the beam’s path.

With proper safety procedures in place, and by following guidelines which accompany your laser welding systems, these hazards should be greatly minimized.

Skin and Eye Hazards

Due to laser engraving safety checks in place, the effects of lasers on skin are usually considered of secondary importance. Compared to laser welding and engraving systems, high-powered infrared lasers utilized in applications for welding and cutting pose a much greater risk of injury.

Some potential effects that can occur if safety procedures are not followed include mild reddening, blistering, and charring, all of which are usually reversible or repairable. Other potential issues could include ulceration, scarring of the skin, depigmentation and damage to underlying organs.

In regards to eye safety, some forms of laser beams operate at a wavelength which if exposed to the eye can pass beyond to the retina. With no pain indicators present and the beam being invisible, someone exposed can be unaware at the time of occurrence.

This is just another reason why utilizing industry-standard laser safety glasses is so vital to maintaining a safe and healthy workspace.

Electrical Hazards

An additional hazard that can be posed when using laser systems is that of electrical shocks. Some of the ways shocks can occur is through contact with:

- Exposed utility power utilization

- Device controls

- Power supply conductors operating at potentials of 50+ volts

Operators and service workers for laser welding systems must be especially careful to avoid these dangers by following standard safety protocols. These hazards could be experienced during:

- Set-up and installation

- Maintenance and service

- Troubleshooting, if equipment protective covers are removed

The electrical injuries that can be sustained from improper and haphazard use of laser systems can include everything from a slight tingle to serious bodily injury to death. To avoid accidental contact with these energized conductors, laser welding units utilize a barrier system within the equipment.

Safety Classifications

Depending upon the risk of a specific type of laser, it is graded from Class I to Class IV. Laser welding machines tend to be graded as Class IV lasers, making laser welding safety all the more important.

Two important additional classifications to keep in mind are the Maximum Permissible Exposure (MPE) and Nominal Hazard Zone (NHZ) designations.

- Maximum Permissible Exposure – This is the highest level of laser radiation an individual can be exposed to without receiving harmful physical effects to the eye or skin. Control measures for laser welding systems are in place to ensure any laser radiation emitted falls below the MPE.

- Nominal Hazard Zone – To create conditions for flexibility in laser welding applications, the laser beam of the unit is often not fully enclosed for practicality reasons. In these instances, it is necessary to define an area of potentially hazardous laser radiation, which is the NHZ. Control measures are then put into place for this area to ensure safety during use of the laser system.

Being fully aware of these classifications and their rationales are vital to ensuring proper workplace laser welding safety.

The Importance of Laser Danger Marking Safety

With the constant changes coming to the industrial and manufacturing sectors, and advanced equipment like laser welding systems becoming increasingly prevalent, it’s more important than ever to be aware of laser danger marking/indication safety procedures.

These procedures range from ways to protect from bodily harm while utilizing Laser Welding machines to ways to avoid electrical dangers on the factory floor. It’s important to know what all of these dangers are and how to train yourself and your staff in essential laser safety.

Rules of conduct on the safe use of lasers

The following rules are of particular importance:

- Never point the laser beam at anyone’s eyes!

- Do not look directly into a laser beam!

- Always wear protection glasses!

- If the laser light accidentally strikes your eyes, close your eyes and immediately move your head out of the laser beam.

- Do not use any focusing optical device to look at the laser beam while working with lasers.

FUMES, SMOKE AND MISTS DANGER AT LASER WELDING

Lasers easily melts, boils and vaporize metals. In doing so, fumes and mists are created which can present a respiratory hazard. Often the fumes and mists cannot be seen, yet they can pose a serious health hazard. Always use adequate ventilation.

Air emissions from welding: radiation, fumes, dust

First of all, we need to talk about the most dangerous emissions into the atmosphere from welding, both for professionals and for those who use the finished product.

One of the most important risk factors for you, especially for operators, comes from the radiation emitted during welding: the most dangerous are ultraviolet radiation, as it is absorbed almost entirely by the skin and eyes. As Photonweld laser welding machines only use Infrared laser, this results in a minimal UV light generation and a minimal danger of UV damage. The protection of each exposed area is the most effective solution. Much les dangerous is the infrared light radiation.

Welding fumes, on the other hand, are a very different problem: the effect changes according to the welded metal, going from problems with the respiratory system to damage to the skeletal system. For this reason, during welding, the work area must be well ventilated, or equipped with the right suction machinery.

Another element that requires suction are the so-called welding powders, very small particles of material with high toxicity and capable of penetrating the respiratory system. Electrode welding has the highest concentration of dust among all welding techniques, so you need to protect yourself with a mask

INFRA RED HEAT RADIATION DANGER AT LASER WELDING

Invisible Infra-red light radiation is used when laser welding. Due to the interaction with the workpiece, high levels of hazardous infrared-A and secondary radiation can produced by reflection. This light radiation is often reflected from the workpiece into the work area. Radiation from laser welding processes can seriously burn eyes an skin quickly and permanently.

Danger of Laser radiation

Lasers used for welding applications radiate in the infrared spectra, which are not visible to the humaneye.

The intensive fiber laser light radiate in the visible spectrum but invisible for humans, is especially dangerous to the eye. Fibre laser radiation penetrate through to the retina which can be destroyed irrevocably by relatively little radiation.

Misdirected laser radiation can come directly from the laser and threaten the eyes as a result of a faulty parameter setting, an opened cover, a displaced mirror etc. Other hazards include skin burn or inflammation from combustible materials as a result of misdirected laserradiation. The greatest hazard, however, usually stems from reflected laser radiation: the major share of the laser radiation is reflected by coldmaterial first. To this we can add reflections of work piece edges, as a result of turbulence in the weld pool etc.

Misdirected radiation and reflections must be blocked off. That is why the law stipulates that the laser beam and the work zone must be in an enclosure. Beyond that, all those present, and the machine operators in particular, should wear protective goggles that are appropriate for the laser radiation being used. Fbre laser radiation are very dangerous to the eye and require special protective measures andapproved safety goggles.

Standard protective welding goggles made of glass or acrylic glass are not suitable at all,

as glass and acrylic glass allow fibre laser radiation to pass through!

FIRE DANGER AT LASER WELDING

Since the laser system produces a very small spot size with high energy, the hazard of fire is present if the beam hits flammable material. Keep flammables away from the welding or cutting area. Be sure to cover and protect anything flammable in the area, since reflected radiation could start fires in unexpected places. Protect the work area.

MECHANICAL DANGER AT LASER WELDING

If the the optical laser device is mounted on an robotic arm or other beam manipulator, these can malfunction and send the laser beam in unintended directions. Therefore, it is essential that the work cell be shielded in conformance with standards for the laser type and class.

ELECTRIC SHOCK DANGER AT LASER WELDING

Since lasers require a large amount of electrical power to accomplish specific tasks, electrical hazards are present. Conventional hazards associated with any electrical industrial power source are present. These require standards and common electrical safe practices as found in Safety and Health Fact Sheet . There are the unique electrical hazards common to lasers in general and the hazard of the individual application. Usually, the best source of safety information is provided in the instruction manual from the manufacturer of the laser system. Always read, understand, and follow the manufacturer’s recommended safety procedures.

A WORLD-CLASS LASER WELDING MACHINE MANUFACTURER

PhotonWeld Series: Full CE Safety certified Handheld Laser Welding Machines

Equipped with all CE requested Safety accesoiries connections as standard

- Laser beam Emission indicator + external emission warning indicator control

- Remote interlock connector with Multi safety interlocks:

- Nozzle contact interlock

- Door contact (external) interlock

- Foot pedal (dead’s men pedal) interlock (opt.),

- Hardware Key control lock

- Internal and external double wired emergency stop (opt.)

- Failsafe start-stop control

- Active Control of start and stop from external fume extraction system

WE HOLD SAFETY OF PEOPLE IN HIGH ESTEEM!

How to build a laser welding safe working zone in your workshop?

How to build a laser welding safe space in your workshop?

Class 4 Laser Operation Requirements for Safe Working

If you want to know how to make your safe laser welding zone:

Click here for info on laser safety cabins/laser safety rooms

Safety for your EYES

Safety Eyewear for laser Welding

Our Selection of Special Laser Welding protection Goggles and faceshields

Check more on Safety for your Eyes - Check our Safety Eyeware