A World of Laser Welding Possibilities

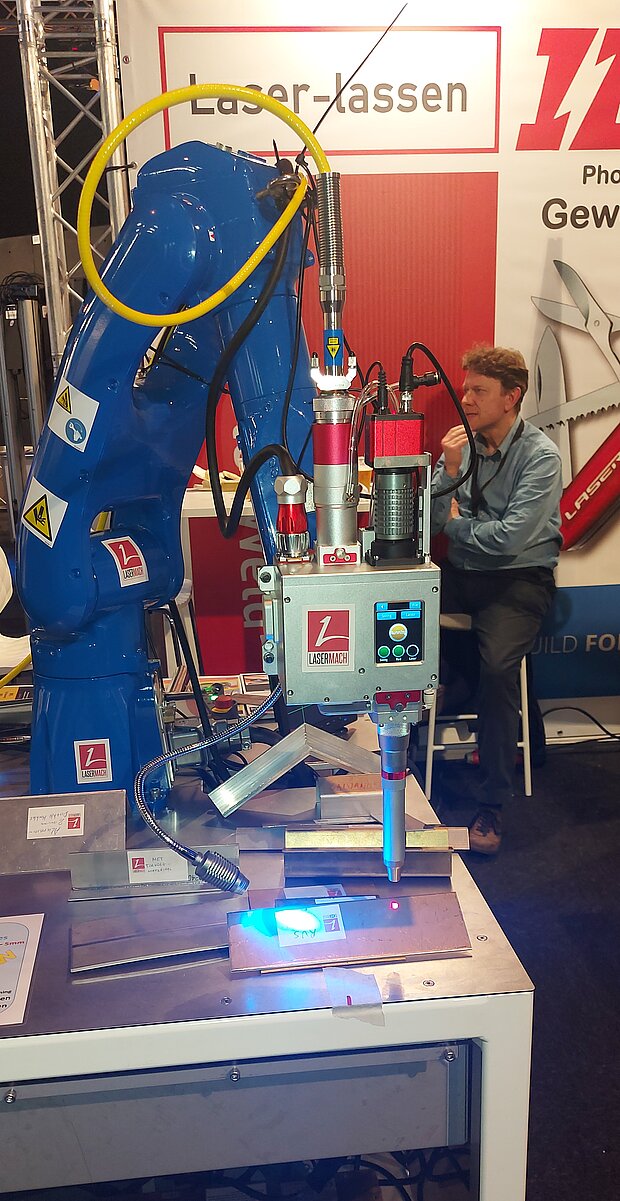

Pre-Engineered Robotic Laser Welding Cells - PhotonWeld-R ROBOT TurnKey Automation Solutions

Lasermach's robotic laser welding systems are pre-engineered, pre-assembled and shipped ready to weld - delivering the most flexible and cost-effective options to integrate robotics into your welding processes. PhotonCube® can be configured with multiple robots, a heavy-duty positioner or servo-controlled external axes for coordinated motion.

PhotonWeld R-Series

Robotic Laser Welding

Producing faster, with consistent quality and the lowest possible costs – those who want to withstand today's tough competition have to rethink. The shortage of skilled workers and increasing lots are pushing manufacturing companies to their limits. In the end only the step towards automation helps. But small and medium-sized companies in particular often hesitate because the uncertainty in the investment is too high – but it doesn´t have to be a fully automated welding robot!

Custom special machines

Thanks to our years of experience in laser welding, we offer highly complex special solutions, from design to commissioning on-site for all highly-specialised industries. We provide full investment and planning security, and offer reliable warranties. This applies to new procurement as well as upgrading and modernising an existing system.

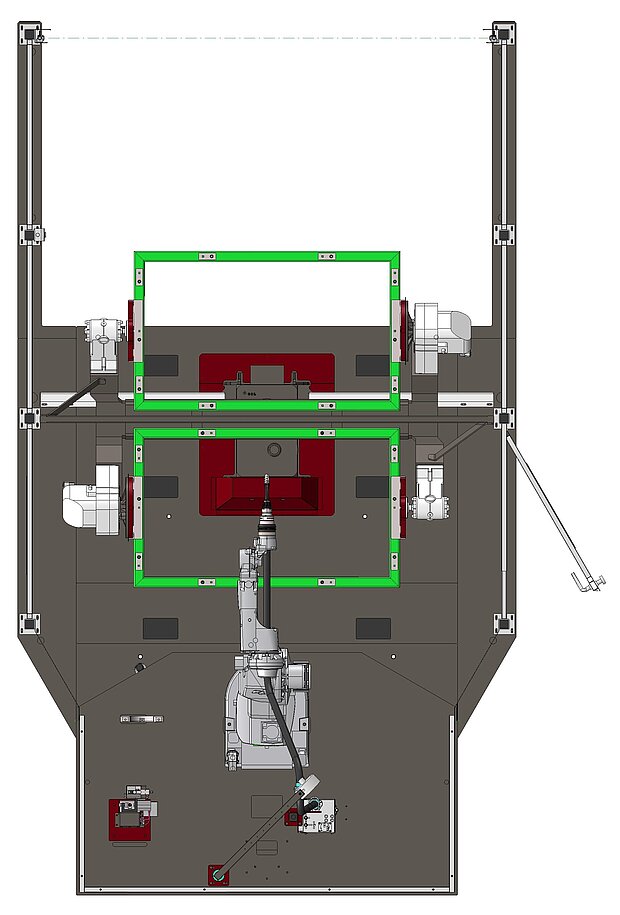

Robotic Laser Welding Cells

Pre-Engineered Laser Welding Cells

Laser Welding Robots

Pre-engineered welding robots ready to be integrated

Ready to run Robot/cobot laser Welding Plug-in units

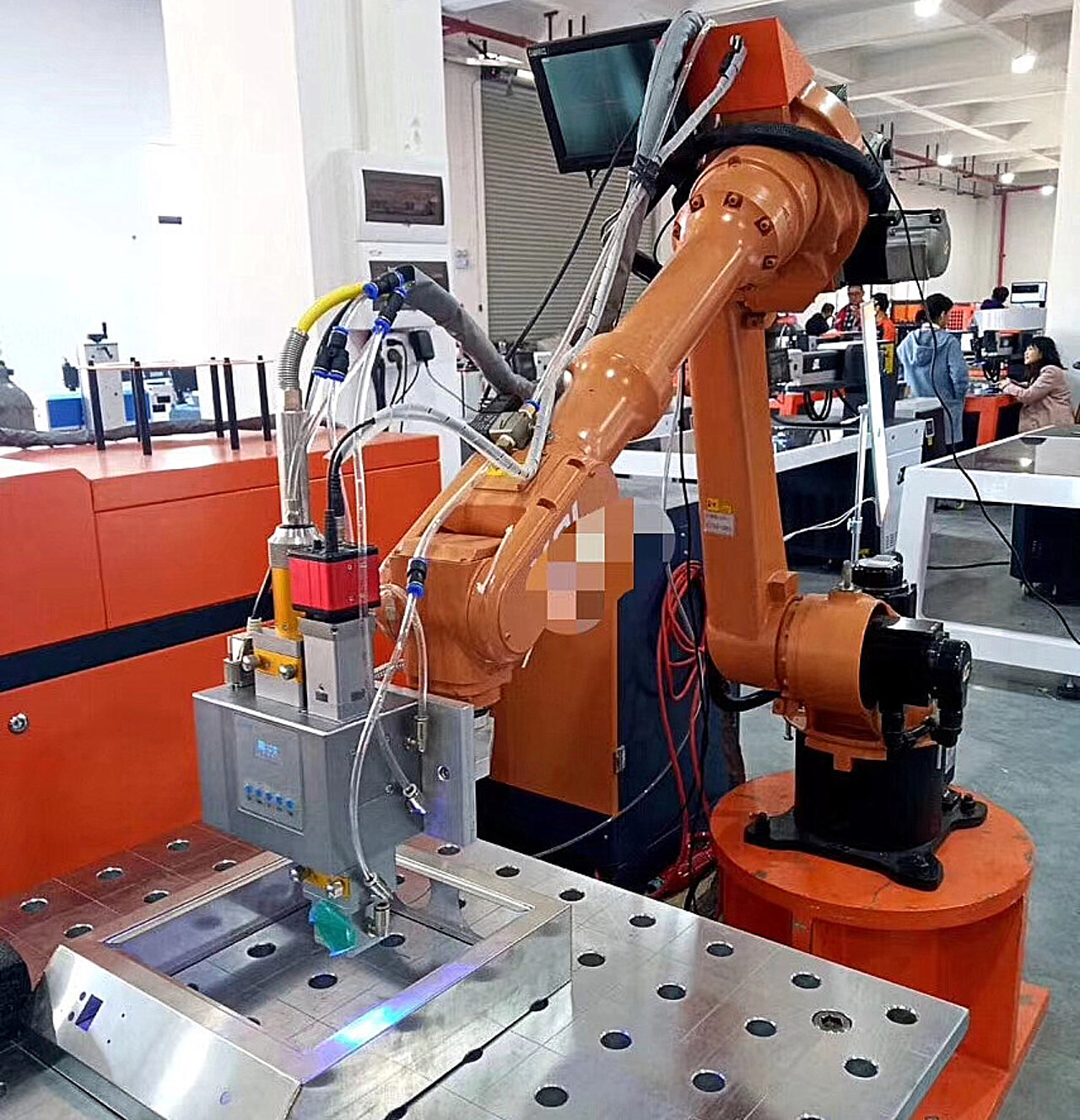

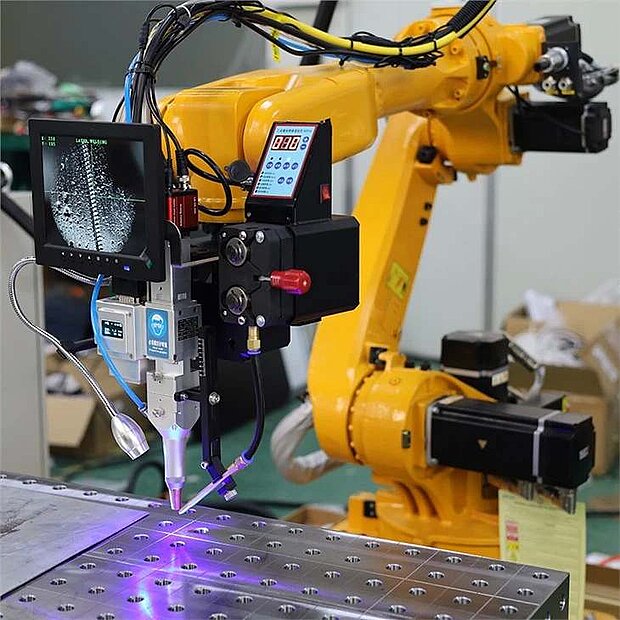

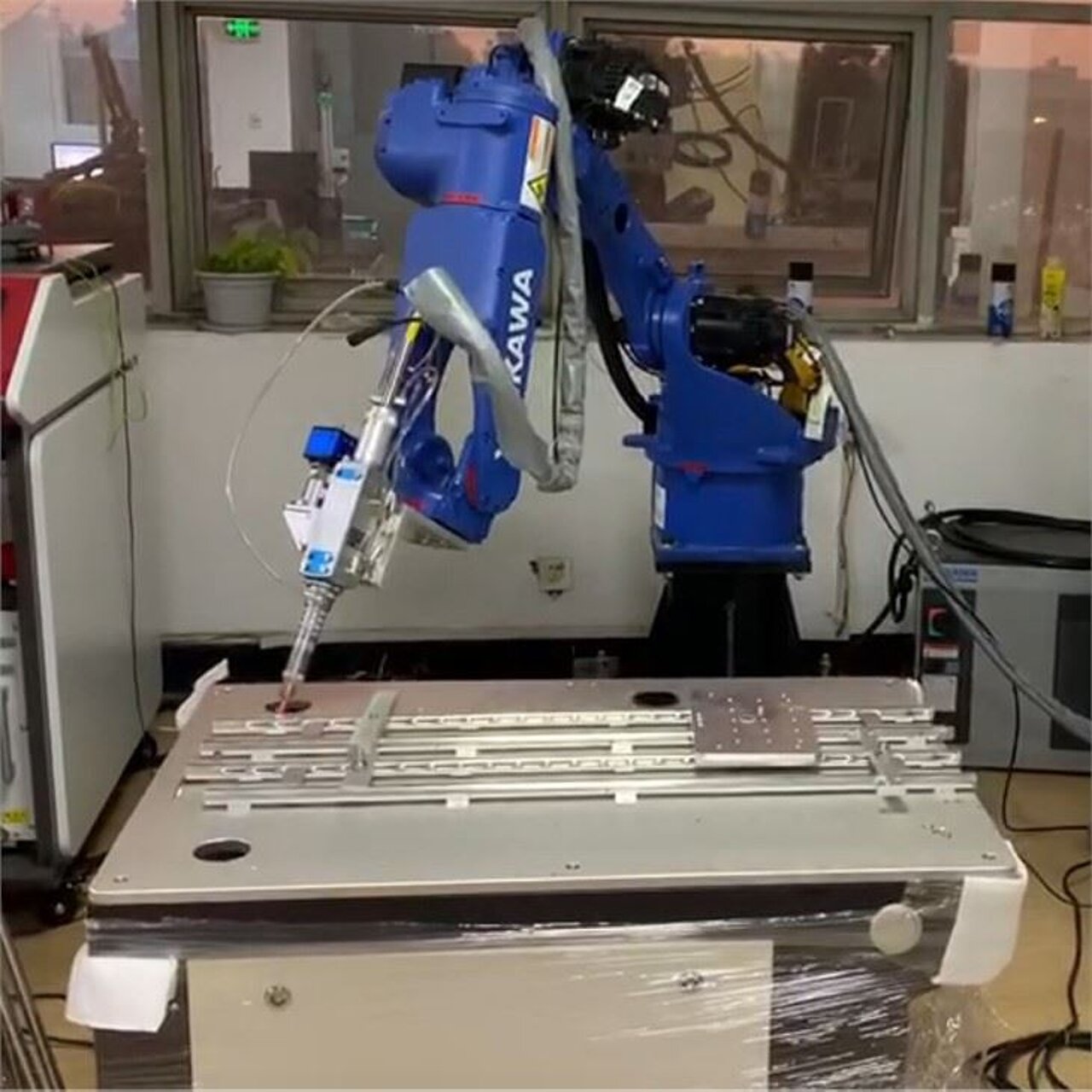

Ready made laser Welding Packages for ROBOT/COBOT and other automations - ROBOT/COBOT ready Laser Welding Packages

Robotic Welding Cells

Robotic welding cells are confined cubicles designed to contain the welding robots so the arms can move freely and navigate around easily without the risk of damaging other components or harming the operators.

The welding cell includes metallic barriers, weld robots, and components required for the robot to operate, such as the torch, power supply, robotic positioners, and other welding fixtures. It will also have arc glare shields, light curtains, laser scanners, and other safety equipment. The advantage of these features of robotic welding cells is that —

- The flexible robotic arm can reach and weld in difficult spaces and complex geometries

- The cell barrier will protect the operators from unwanted glare and splatter

- The cells equipped with proper ventilation hoods efficiently extract the hazardous fumes

- The robotic arm can be extended to move within the well-engineered cell layout, so it does not interfere with other equipment or manual workspaces

In addition to these operational advantages, the increasing adaptation of weld robots and robotic welding cells also means the following —

- The automated weld robot runs at a set speed and process parameters during each pass, producing consistent, uniform, and high-quality results.

- The predictable performance of the robot makes it easy to take on the attainable job and precisely deliver, especially when the demands fluctuate.

- The automated robotic system enhances productivity for manufacturers during the welder shortage.

Weld robots can produce repeatable results at a consistent speed with less waste, unlike manual welding, improving the cost efficiency of the process.

ROBOTIC WELDING IS A WORTHWHILE INVESTMENT. AND NOT JUST IN SERIES PRODUCTION!

FLEXIBLE, USER-FRIENDLY AND COST EFFECTIVE

The industry is undergoing increasing transformation, and so too is welding. Until recently, what would have been welded manually is now welded automatically. There are many reasons for this transition. More and more companies are demanding both consistent, high welding quality that can be reproduced at any time, and full documentation of all welding parameters. Ever-tightening safety standards and a chronic shortage of skilled workers are also having an effect. Robotic welding solutions are now becoming increasingly smart, more collaborative and completely cost effective, even for small and medium-sized businesses. This is all thanks to offline programming, system autonomy and extremely fast setup times from a batch size of just one.

Robotic welding offers optimal solutions for unleashing your welding potential.

Robotic Welding Cells Layout

The ability to leverage quality weld from robots is directly related to the ability to efficiently layout the robotic welding cells. Therefore, here are some critical design considerations to note.

- The cell should be wide enough to accommodate the largest part size and strong enough to handle the weight of the heaviest workpiece and tools.

- The movement of the robotic arm within the cell can be programmed using offline modeling and simulation tools. Any errors can be easily identified and corrected so that the robot can perform according to the programmed weld sequence.

- The workpiece supply into the robotic welding cell must be streamlined to avoid interfering with the ongoing operation.

Our base model PhotonWeld-R has a single robot interface suitable to most of the robot brands.

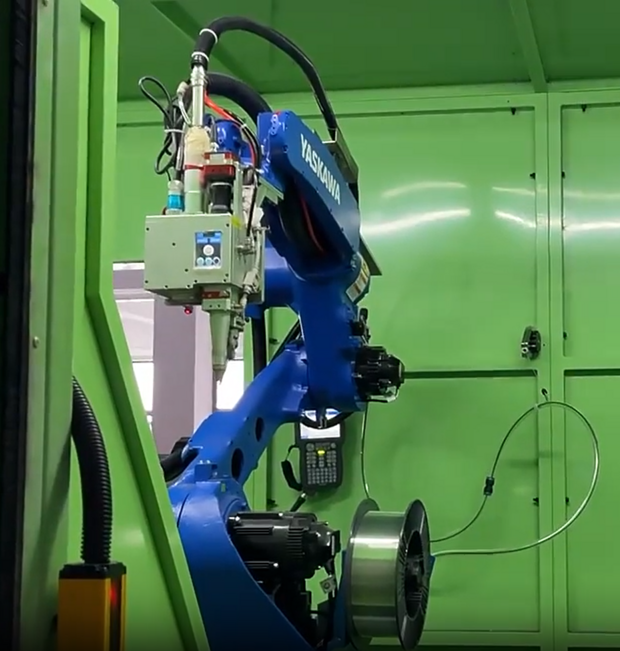

Our PhotonWeld-R units suits following Robot brands

Fanuc Robotics

Yaskawa Robotics

Panasonic Robotics

ABB Robotics

Kawasaki Robotics

Nachi Robotics

Denso Robotics

Kuka Robotics

Mitsubishi Robotics

Epson Robotics

Stäubli Robotics

Foxconn Robotics

Comau Robotics

Omron / Adept Robotics

Universal Robotics

JAKA Robotics

AUBO Robotics

SIASUN Robotics

BORUNTE Robotics

QJAR-EVS Robotics

ESTUN Robotics

Inovance Technology

….

and more

Safety is a basic criteria

Build your Robot/cobot cell with safety of people in mind!

Laser welding can be a dangerous application for people. Consequently, it’s essential to implement safety measures to protect employees. Risk mitigation measures commonly include:

- Safety guarding/enclosure

- Light curtains or door locks

- Optional Safety scanner(s)

- Lock-out/tag-out systems

- Live-man switch 'optional)