Fume, Fog, mist is blocking any sort of light, especially laserlight!

Without fume extraction, its like driving in the heavy fog.

Because source fume capture does remove fume at the source, it keeps the efficiency high of your laser welder

You can weld better, faster and with bigger efficiency with direct source fume extraction!!

Source Fume extraction is very important for the laser welding efficiency

Source fume does limit the efficiency of the laserbeam

Besides toxicity and other reasons to collect weld fumes, such as safety regulations, laser welders need a fume free environment so the laser can perform at its optimal level.

If fume builds up near the laser, the particles within the fume can refract the laser beam, making the process both less efficient and less precise.

It is like driving in fog with your lights on. Fog or no fog makes a huge difference in visibility, this is the same for laser welding as we also use light! Without fume (even invisible) the laser light reaches fully the welding parts without diffraction.

You can weld better, faster and with bigger efficiency with direct fume extraction!!

Because source fume capture does remove fume at the source, it keeps the efficiency high of your laser welder !

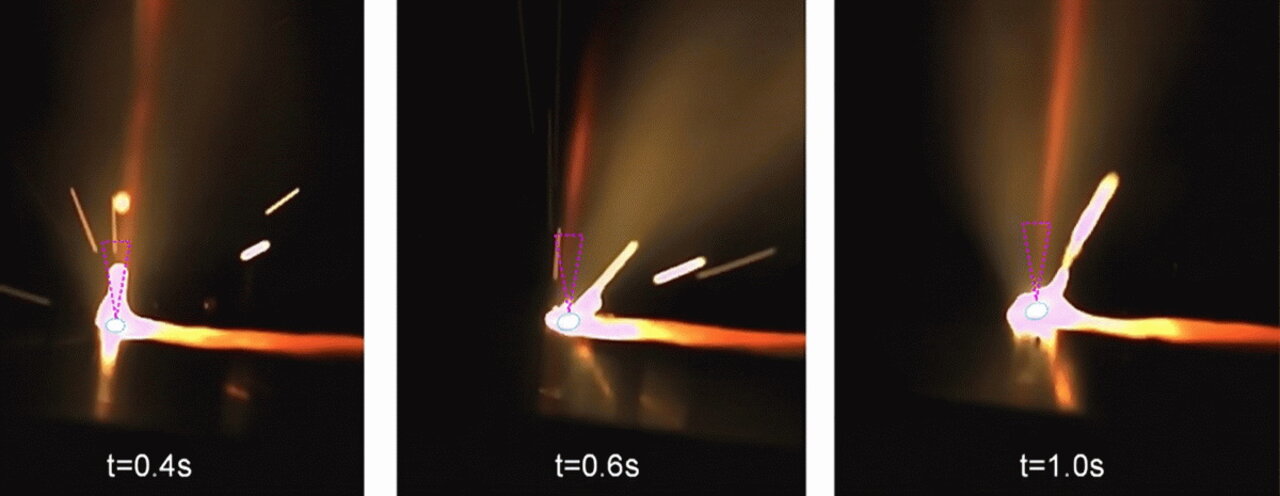

Invisible laser welding plume reducing the efficiency of the laser beam

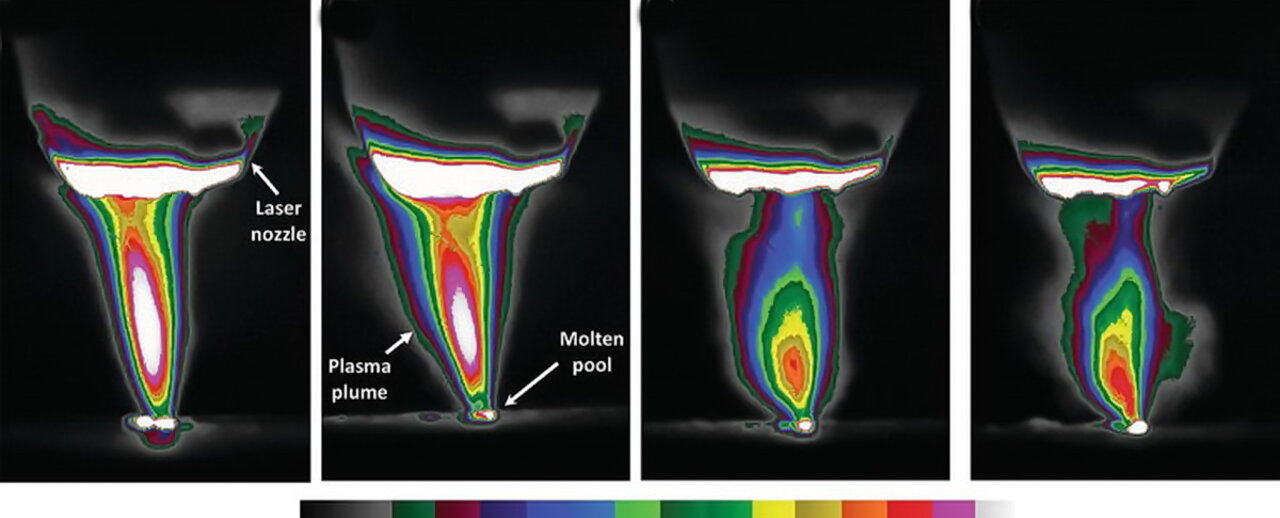

Infra red picture of the laser welding beam efficiency reduction by welding fume

How an invisible laser welding plume is formed made visual by a thermal camera

The laser welding plume forming is blocking the laser light and reduce the efficiency of any laser Welding Machine: this is why we need "on the source" fume extraction

Ventilation Solutions for Laser Welding

Why we recommend direct capture of the laser Welding fumes on the welding spot?

Laser welding is a rapidly growing process in manufacturing and is popular due to its high level of precision and efficiency. While the initial investment for laser welding systems is higher than most other systems, the benefits are profound in terms of ability and speed. However, laser welding operations incur serious challenges when it comes to weld fumes.

Because laser welders operate at such high temperatures, their weld fumes are full of very small particulates. The smaller the particulate, the more inhalable and dangerous it is for workers.

While an fully automatic laser welding machine/robot functions in an enclosed cell—one without a human operator—it is still very important to capture the fumes inside the cell. Source capture by Flexible vacuum tubes by or enclosing hoods are the most effective in controlling contaminants at handheld laser welding

When Laser welding with a handheld laser welding machine, it becomes even more important to capture the fumes and microscopic dust before the welder can inhale. Therefor every welding cell for manual welding should have a fume filtering system directly on the welding action place.

Besides toxicity and other reasons to collect weld fumes, such as safety regulations, laser welders need a fume free environment so the laser can perform at its optimal level. If fume builds up near the laser, the particles within the fume can refract the laser beam, making the process both less efficient and less precise.

Source capture is the most effective in controlling contaminating welding fume!

Because source fume capture does remove fume at the source, it does limit immediate exposure at the worker’s breathing zone.

Perform Source Capture to Improve Efficiency

Welding fume capture is most effective when a fume extraction nozzle is positioned next to the source of fumes. If you can’t position a nozzle in that area because you have mechanical constraints, fume extraction should be as close as possible. If the laser moves during the operation, the nozzle should follow the laser beam to maintain the efficiency of fume extraction.

If multiple processes generate fumes, a single fume and dust collector can be used. For example, manufacturers who perform laser cleaning at the same time as welding can have a single welding fume extractor.

How Much Airflow Is Needed?

The volume of airflow needed is directly related to the amount of material removed. While laser welding removes little to no material, other processes like laser cutting and laser cleaning remove important quantities of material and require a higher airflow.

How Are Contaminants Filtered?

Air can be filtered using two main methods: Either you connect the laser fume extraction system to your in-house duct system, or you buy a filtration system. Whether air filtration is done through ducting or in a standalone unit, there are typically three main types of filters. The resulting air quality is 100% safe for employees. Once filters are saturated, they need to be changed to maintain their efficiency and ensure a clean air.

- Pre-filters: Pre-filters capture large particles that are visible to the human eye.

- HEPA filters: High Efficiency Particulate Air filters capture small particles such as fine dust through layers of fibers. These filters can remove at least 99.97% of particles with a size of 0.3 microns.

- Activated carbon filters: Carbon filters capture and neutralize Odors, smoke, fumes and chemicals. When these contaminants pass through, they are trapped in the small pores of the activated carbon.